I came upon a great article entitled The Time Is Now (available only to ASQ members), by Narahari Rao. It describes how orders, invoices, transactions, testing & inspection reports, material certificates, and other critical pieces of information could all be saved in a blockchain database.

What is the advantage?

Let’s say your company buys products that require materials from different suppliers and sub-suppliers. To understand what happens in your supply chain, manage risks (think ‘traceability’), and improve performance (e.g. only check each product property once), you need to have visibility over all these data.

The idea is to record all these data on a special ledger, which can be public (in which case the records are quasi-impossible to modify) and/or private.

But first, what is a blockchain?

It is a type of database that is not owned/controlled by one organization and, when designed to be public, is very difficult to hack & modify.

This article does a great job of explaining the basics of this technology in a simple way, with graphics.

How can the key records of a supply chain be saved in a blockchain ledger?

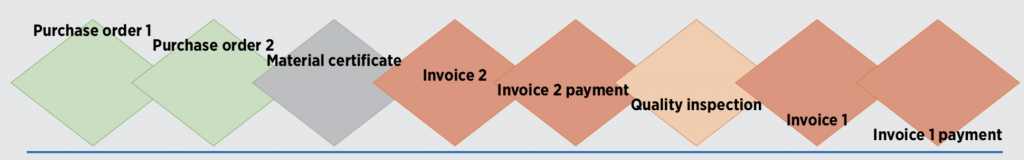

Rao’s article represents it this way:

The blockchain database would log this information and timestamp events. The records would remain accessible, which gives visibility over what really happened.

Is it only helpful on the quality side?

No. Rao’s article focuses on the implications for quality & safety management, but that’s only part of the story.

For example, it can help with equipment maintenance. Proper maintenance is essential to ensuring safety in the aviation industry, therefore some airlines are looking at ways to apply blockchain technology to track workflows.

As James Kornberg, innovation director for Air France KLM, declared:

The four features of blockchain are resilience, traceability, integrity and disintermediation [and] are well suited to the aviation supply chain.

Another example: tracking environmental risks among your Chinese suppliers and sub-suppliers, at a time when polluting operations get closed immediately upon government inspection. I drew a chart about this before.

Is it only helpful for compliance (quality, safety, environmental impact…)?

One can imagine all types of applications. For example, having transactions completed automatically based on pre-defined “smart contracts” (to replace letters of credit), and in small increments (since wiring a cryptocurrency such as XRP costs nearly nothing).

Time will tell what uses will go mainstream.

Note: many people have tried to apply this technology to problems that are already solved. There has been much hype, and some people have raised considerable amounts of money in a totally unregulated manner (through an “Initial Coin Offering”, which is akin to a casino that sells its own token to play a certain game). I am quite dubious about many of those projects.

Another benefit is transparency. A growing number of companies (Patagonia, H&M, Apple…) have made their supplier lists public. There are several objectives (consumer pressure and brand image, compliance and sustainability…) and this trend is here to stay. Logging a lot of information on a public blockchain ledger would be the ultimate mode of transparency!

Which part of the supply chain will implement it?

It needs a spark to come to life. Here is how I see it:

- A buyer with sufficient control over its suppliers can do it. Don’t be surprised if Amazon starts to require some data to be logged about the products they sell (about the materials origin, testing certificates, etc.). In case something turns really bad and there is an investigation, that buyer can show all the data in a way no player could falsify.

- Similarly, a government body could require all importers of a certain class of products (e.g. medical devices) to log some key information. (Note: having said that, that body could simply log all the information in a centralized database under their control, and it would probably do the job as well.)

Could it become standard across an entire country, or across an entire industry?

I believe so. Let’s take an example.

The EU requests importers to keep a “technical file” in good order for at least 10 years after any product has been put on the market. It typically includes the following data:

- Design files (drawings, schemas, etc.)

- Certifications about the factory (ISO 9001, SA 8000…) and about some sub-suppliers’ factories

- Bill of materials (i.e. list of components and materials)

- Certifications of compliance on some components that go into the product

- Certifications of compliance on the product: chemical (cadmium, phthalates…), safety (low voltage, EMC…), etc

- Declaration of conformity of the product, for example for CE products

- Laboratory tests during production

- Product inspections in the factory, whether first party (manufacturer) or second party (buyer)

- Packaging information (artwork, manual, labeling, etc.)

- Other documents, as requested by the buyer

In both cases, the buyer (the car OEM, or the importer of record) could be requested to keep all these data in a blockchain, allowing investigators to have easy access to data that can’t be falsified.

What do you think?

Is it a “solution in search of a problem that doesn’t exist”? Or will it become mainstream in international trade?