China supply chain transparency and monitoring is still as important an issue as it has ever been, and importers need to stay on their toes.

Let’s explore why this isn’t getting any easier…

The importance of transparency in the supply chain

Most Chinese manufacturers routinely subcontract some of their production without informing their customers. They see this as a necessary rule of the game.

More and more importers are aware of this risk and try to prevent it (I wrote about 8 ways to do prevent subcontracting before and also looked in more detail at Chinese manufacturing contracts which can protect you), as quality often suffers and social compliance standards can’t be enforced.

These days, all brands know the importance of transparency, and the companies doing final assembly (or cut & sew, in apparel) know they are watched.

However, further down the supply chain, unauthorized subcontracting is still very, very common.

We noticed this is particularly true of metal surface treatment processes that are done outside of the “main factory” (which would typically do casting and CNC lathe/milling). A few examples:

- Plating

- Polishing

- Painting, coating, e-coating, anodizing

These processes, if they are not done well, create aesthetic issues and longer-term protection and/or performance problems on the product. They are often among the most critical process steps when it comes to ensuring product quality!

And yet, they are usually outside the “main factory”. There are several reasons for that:

- As environmental regulations and enforcement got tighter in China, obtaining and keeping a license to carry out these potentially high-water-pollution activities has gotten much harder. Not to mention, the entire facility might get shut down overnight after a government inspection…

- Most of the plating, anodizing, and e-coating is now done in relatively large specialized facilities. Chinese managers always tend to look for economies of scale, and they prefer subcontracting to a specialist and negotiate hard on pricing (rather than doing small-scale operations in-house).

Assessing your risks

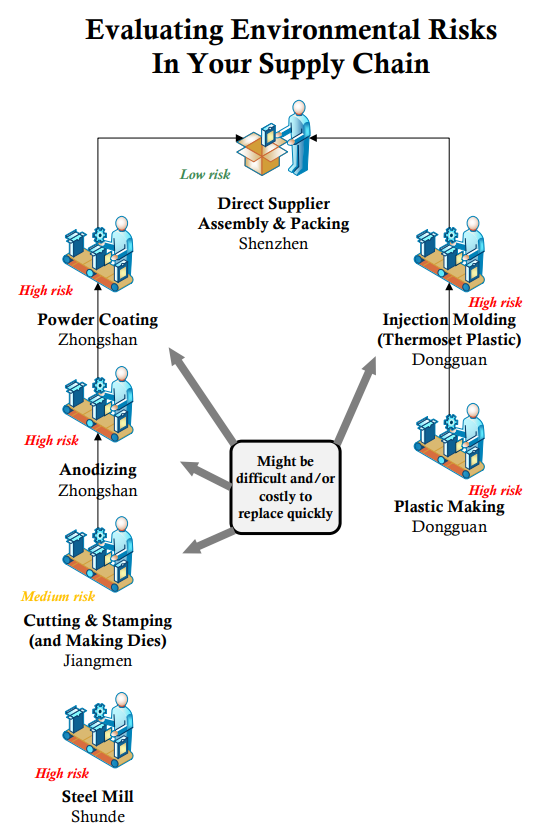

If you don’t have full visibility into where your products are processed, you can’t assess your risks. I wrote about this before, and I drew this little illustration:

In this example, if anodizing and powder coating takes place in shady facilities, it can have serious impacts:

- There might be serious quality issues on the product.

- They can be shut down at any time, endangering the continuity of supply.

If you did a great job qualifying component suppliers, and you have visited those surface treatment facilities when first vetting the metal supplier; the bad news is, you need to keep monitoring whether these processes really take place in the facilities you approved.

***

Have you had any experience with a lack of transparency in your China supply chain? How do you go about monitoring your suppliers and wider supply chain? Let me know by leaving a comment, please.

Are you wondering how to find a manufacturer in China who is well-suited to your needs and can also deliver on their promises?

Sofeast has developed 10 verification steps to help you find the right manufacturer. They’re shared in this FREE eBook: “How To Find A Manufacturer In China: 10 Verification Steps.”

It covers:

- Background checks

- Manufacturing capabilities

- Quality system auditing

- Engineering resources

- Pricing, negotiation, & contracts

- …and much, much more

Just hit the button below to get your copy:

Achieving supply chain visibility is a global issue. It’s notoriously hard for companies to manage their overseas suppliers, especially when attempting to go beyond the first or even second tier. According to the prominent China Biz Lawyers, decoding the differences is not an insurmountable challenge but it takes patience, curiosity and a disciplined approach to supply chain management.