Last week, I was happy to moderate a seminar organized in Shenzhen by the European Chamber. The three speakers, who were kind enough to come and expose the programs they use for developing good Chinese suppliers, represented very diverse organizations:

- A retailer (Kingfisher, with more than 1,000 stores, mostly in Europe);

- An industrial organization (Altra Industrial Motion);

- A high-tech company in the security field (Oberthur).

After looking at my notes, I noticed that a supplier development program follows logical steps:

I am going to describe each of these building blocks next.

1. Selecting suppliers that can improve over time

Oberthur pays a lot of attention to the type of suppliers they work with. Here are two of their supplier selection criteria:

- Some manufacturers have a “culture” that pushes them to search for improvements, naturally and without the need for pressure coming from key buyers.

- Some suppliers have an interest in developing new products. Widening their product range is part of their strategy, so they are ready to invest time and money in a difficult development process (see part 2 below).

2. From quotation to the first production batch

The manufacturer needs to understand the buyer’s expectations, and the development of customized products can take a long time.

This is how Altra Industrial Motion develops its new suppliers:

- Explanation of their requirements;

- Explanation of the proposed production process (they are familiar with the production of the components they purchase);

- Analysis of the factory’s inspection methods, and corrections if necessary — they estimate that the cause of 50% of their quality problems is a lack of knowledge of proper inspection methods at the factory level;

- Feedback on pre-production samples until they are right.

3. Ensure a minimum quality level

If a supplier cannot reliably deliver products that satisfy the buyer’s quality standard, the priority is to push them to get their quality under control… or to stop the relationship.

But how to push a supplier to improve its quality, without spending a huge amount of work?

- By auditing their quality system, pointing deficiencies to their attention, and helping them implement corrective actions.

- By studying the most frequent types of defects, running a root cause analysis, and pushing for implementation of countermeasures.

This is at the heart of Kingfisher’s supplier development program. They want more suppliers to “self-inspect”. The objective is to avoid the cost of third-party inspections.

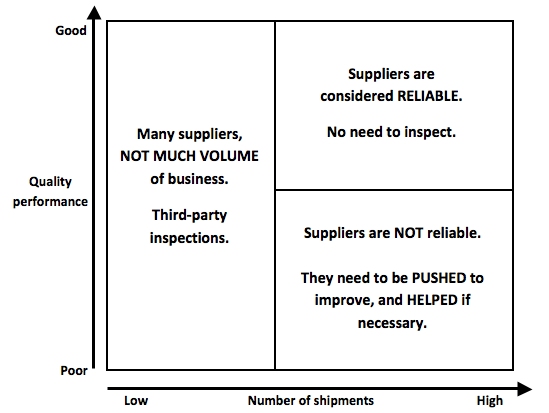

So they focus on their high-volume suppliers with low quality performance (see below chart). Their approach is: “we are going to pay for a program that will make you more competitive in the long term”. If the supplier’s boss is interested, they go ahead.

4. Pick the low-hanging fruits

Most Chinese suppliers have a lot of room for improvement. But they are not always aware of this situation.

The buyer can help the supplier pick the low-hanging fruits by apply a gentle mix of pulling and pushing.

For example, Oberthur has pressure to decrease prices on certain products every year. So they ask the supplier for a roadmap to reduce costs in the coming years (with details on how he intends to achieve these targets).

Another example: Altra Industrial Motion helps decrease the scrap rate once a production is under way (their suppliers do a lot of metal machining, so rejects and scrap are always a problem). This way, less material is consumed. The supplier’s cost is lower. And price increases are less justified.

Altra’s representative said something interesting: “our best suppliers are the ones we visited the most over the last 7 years”.

5. Re-organize production

When a supplier is willing to work on improving his operations, and doesn’t work for direct competitors, it makes sense to help him re-organize production for better results.

This step is comprized on several sub-steps that cannot be skipped:

- The buyer should select a priority: quality, cost, faster production cycle and smaller batches, capacity…

- Select a few KPIs, and track their improvement over the following sub-steps;

- Pick a target, envision the future state that needs to be achieved to meet this target, and then make changes in processes and in the supporting organization to reach that future state;

- Start over again with a new target, after the team got a sense of victory and has the energy to take on another challenge.

This fifth step is all about lean production. It offers impressive results when done the right way. But it is not the first step in a supplier development program.

Do you agree?

—

Names and titles of the three speakers:

- Eva Zhang, Field Operations Manager, Kingfisher Sourcing Organisation.

- Sebastien Binot, ECB Asia Sourcing Manager, Altra Industrial Motion (Shenzhen-China) Co. Ltd.

- Daisy Liu, Asia Head of Purchasing, Oberthur Technologies.

Featured image credit: dhester, image, morguefile CC license

Ultimate Guide To Sourcing From China And Developing Your Suppliers [eBook]

This FREE eBook starts from the beginning, discussing whether you need to hire a sourcing agent, and follows the sourcing process right through to developing a trusted supplier’s quality and productivity.

There are 15 chapters over 80+ pages to explore, providing exhaustive guidance on the entire sourcing and supplier development process from start to finish, including:

- Identifying suppliers,

- Negotiations,

- Quality inspections,

- Developing Chinese suppliers,

- Improving factory quality and productivity,

- and much more…