I have been reading ‘the’ reference textbook on the concepts of DFM and DFA (design for manufacturing and design for assembly).

It’s great for design engineers (especially on the mechanical side), for NPI program managers, and for anybody working on reliability, quality, or costing at the product design stage.

People involved in manufacturing would also benefit from skimming through it.

I picked 2 graphs that are quite interesting.

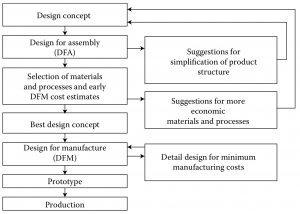

1. The logical steps: first DFA, then DFM

DFM is about the materials & processes to make the components and DFA is about how to assemble those components together. So, one might assume DFM comes first.

Wrong.

The first step is to challenge how many different components are really needed. As the authors show through examples, fewer parts usually come with (much) lower costs.

Once you have gotten to a ‘reasonably minimal’ number of parts, the time comes to find the most economic materials and processes to make those parts, and after that comes the detailed design work of those parts.

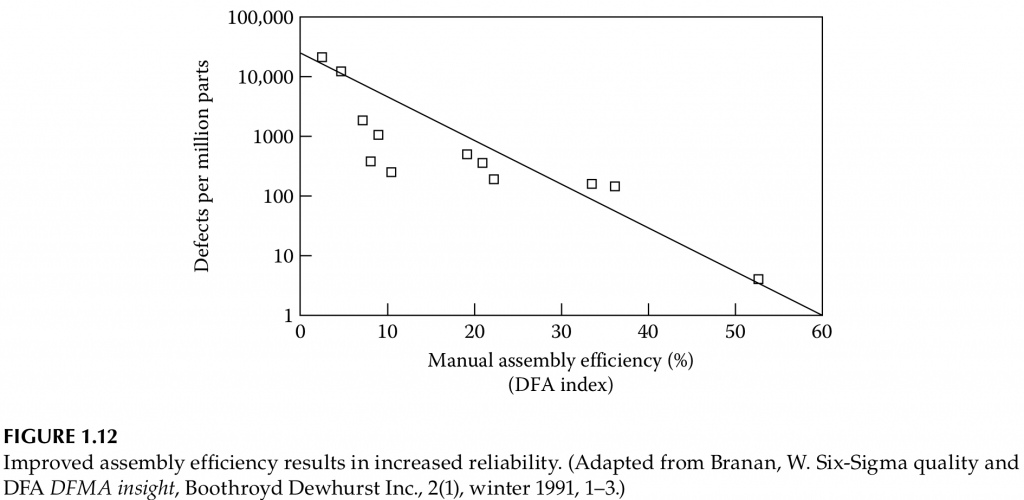

2. Good DFA reduces the proportion of defects on the product

Simpler products come with fewer potential issues, and that usually translates into fewer issues in the hands of users. That’s a simple concept.

I read articles showing that Toyota & Honda cars were more reliable in good part because they kept their cars simpler (with fewer parts, fewer small motors, etc.) than some of the German brands. But I don’t remember reading about direct causal link.

The authors show a nice graph that drives this point home:

If you make assembly more efficient (in good part thanks to fewer components), the proportion of defects in the final product goes down a lot.

******

Does that make sense to you, and have you seen examples of this? Or any counter-examples? Let me know in the comments.