This article introduces the different AQL inspection levels available to buyers. Those levels are mentioned in the ISO 2859-1 standard (or its American equivalent, ANSI/ASQC Z1.4).

Let’s explore the different levels of random inspections, and how they affect the size of the samples your inspector will pull out of each batch during an inspection.

What is ISO 2859-1 / ANSI/ASQC Z1.4?

In more than 95% of cases, quality inspectors who are performing random sampling AQL inspections are following a standard that guides them: ISO 2859-1: Sampling procedures for inspection by attributes — Part 1: Sampling schemes indexed by acceptance quality limit (AQL) for lot-by-lot inspection.

The standard helps the inspector know:

- The number of products that should be taken out as a sample and inspected, based on the inspection level you mandated.

- The AQL (acceptance quality limits) that dictate what percentage of products are permitted to ‘fail’ the inspection before the whole batch is classified as a failure.

The inspector can simply use the ISO 2859-1 master tables, commonly called AQL tables, to calculate the sample size and the AQL limits based on the inspection level chosen. That level should be appropriate to the situation and products (for instance, a higher or special inspection level will be applicable for cases where you have more or fewer suspicions or tolerance of quality issues – more on this later…).

(To clarify: the “level” gives the number of pieces to check, and the “AQL limits” provide an upper limit to defectives. They are separate concepts, but many people say “AQL inspection levels”, meaning “the levels for random inspections”.)

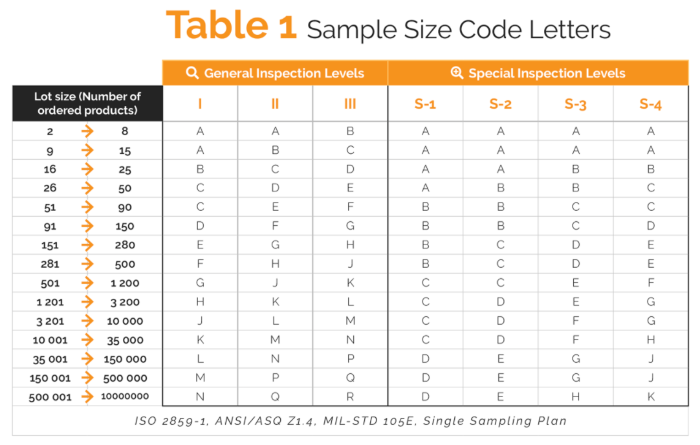

Here is table 1 which is used to get the code letter (to be used in table 2) based on your inspection level:

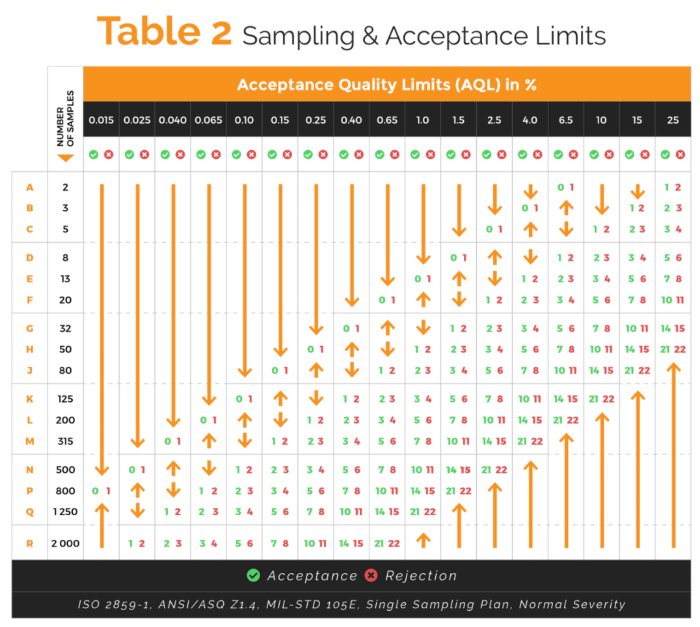

And here’s table 2 which shows:

- The number of samples to pick, based on the code letter;

- The AQL limits based on the sample size from table 1 (the AQL is shown as a percentage, and then as acceptance & rejection amounts in numbers) where the inspector will know which AQL limits you have set, such as 1.5%, 2.5%, or 4.0%:

Related Get help to understand how to read the AQL tables.

Why the need for sampling, rather than checking 100% of the products?

When controlling the quality of a batch of products, in most cases it is not practical to inspect 100% of them (unless the quantity is very small). Inspecting a large number of products takes a long time: it is more expensive, and inspectors are less effective as they get tired.

100% inspections make more sense with high-value products, like hand-made watches, or as an extreme measure if your random sampling inspections keep finding failed batches of products from one supplier over time.

In general, though, a 100% check does not yield that much more information than inspecting a statistically representative sample.

So, if we’re going to choose a sample of a batch to inspect, the question becomes: how many products to check?

Why are there different AQL inspection levels and how do they affect sample size?

There is a fairly obvious principle in statistical quality control: the greater the order quantity, the higher the number of samples to check.

But should the number of samples ONLY depend on the order quantity? What if this factory had many quality problems recently, and you suspect there are many defects? In this case, you might want more products to be checked.

On the other hand, if an inspection requires tests that end up in product destruction, shouldn’t the sample size be drastically reduced? And if the quality issues are always present on all the products of a given batch (for reasons inherent to processes at work), why not check only a few samples?

For these reasons, different levels are proposed by MIL-STD 105 E (the widely used standard for quality control in the form of acceptance sampling). By the way, that standard has formally been replaced by various commercial standards (ISO 2859-1, ANSI/ASQ Z1.4, and so forth).

(Clarification: the standards also give us switching rule, and different ‘severities’, to control for the past performance of various factories. However, I am skipping that topic here because, in fact, very very few buyers follow those switching rules.)

It is usually the buyer’s responsibility to choose the inspection level–more samples to check means more chances to reject bad products when they are bad, but it may also mean more days (and dollars) spent on an inspection.

Which inspection level is normal?

Inspection level II (under “normal severity”) is appropriate for the visual check, in most inspections. But they all have a purpose and will be chosen based on the context and the content of the inspection.

What are the inspection levels and when are they used?

The AQL inspection levels that you choose are relevant in different scenarios and you, the importer, need to advise your quality inspector which to follow.

The 3 “general” inspection levels

Let’s examine the more general inspection levels as seen in AQL table 1, and when they’d be appropriate for use:

Level I

Has this supplier passed most previous inspections? Do you feel confident in their products’ quality? Instead of doing no quality control, buyers can check fewer samples by opting for a level-I inspection.

However, settling on this level by default, in order to spend less time/money on inspections, is very risky. The likelihood of finding quality problems is lower than generally recommended.

Level II

It is the most widely used inspection level, to be used by default.

Level III

If a supplier recently had quality problems, this level is appropriate. More samples are inspected, and a batch of products will (most probably) be rejected if it is below the quality criteria defined by the buyer.

Some buyers opt for level-III inspections for high-value products. It can also be interesting for small quantities, where the inspection would take only one day whatever level is chosen.

The 4 “special” inspection levels

Also found in AQL table 1, these special levels can be applied in cases where only very few samples can be checked. “Four additional special levels, S-1, S-2, S-3 and S-4 […] may be used where relatively small sample sizes are necessary and larger sampling risks can be tolerated” (ISO 2859-1 standard).

Under S-3 level, the number of samples to check is lower than under S-4, and so on.

In practice: for consumer goods, visual quality control (i.e. checking the appearance of the products, their basic function…) is usually performed under the general levels.

The special levels are typically used for certain tests that either take lots of time or destroy the samples. Another situation where special levels are appropriate is during container-loading supervision – to have an idea of what is inside the cartons without spending too much time on the inspection.

Two examples to get a clearer understanding of how inspection levels affect sample sizes

How does all of this work in practice, then?

Let’s say you have ordered 5,000 pcs of a relatively simple product. In the table below, you can see how many samples would be drawn under each of the 7 inspection levels.

| General inspection levels | Special inspection levels | |||||

| I | II | III | S-1 | S-2 | S-3 | S-4 |

| 80pcs | 200pcs | 315pcs | 5pcs | 8pcs | 20pcs | 32pcs |

As you can see, the numbers of samples to check vary from 5pcs to 315pcs. But a trained inspector might be able to do it in one day, whatever the inspection level you choose.

Now let’s say you have ordered 40,000pcs of a product. Again, you can see the differences in sample sizes.

| General inspection levels | Special inspection levels | |||||

| I | II | III | S-1 | S-2 | S-3 | S-4 |

| 200pcs | 500pcs | 800pcs | 8pcs | 13pcs | 32pcs | 80pcs |

In this case, the inspection might take one day of work (for S-1, S-2, S-3, S-4, or reduced level), two days (for a level 2 inspection), or three days (for a level 3 inspection).

So again, the inspection level chosen has a close correlation with the cost of and time spent doing product inspections, as well as the level of assurance you’re giving yourself that the product quality is acceptable.

******

P.S. Get even more information on this topic from these posts:

- Why we shouldn’t check 10% of the order quantity

- The different types of sampling plans for QC inspections

- What is the “AQL” (Acceptance Quality Limit) in simple terms?

- How to misuse the ISO 2859-1 standard: sets vs. pieces

- The Different Sampling Plans Contained in the ISO 2859 Series

By the way, we also developed an AQL calculator that you can use to quickly calculate sample size and defects allowed.

Editor’s note: Post originally published in Dec 2011, but revised and updated in June 2021.

Sofeast: Quality Assurance In China Or Vietnam For Beginners [eBook]

This free eBook shows importers who are new to outsourcing production to China or Vietnam the five key foundations of a proven Quality Assurance strategy, and also shows you some common traps that importers fall into and how to avoid or overcome them in order to get the best possible production results.

Ready to get your copy? Hit the button below: