A lot of entrepreneurs and SMEs struggle to calculate their investment for launching a new product. This can lead to unexpected costs mounting up and, eventually, needing to sell at a loss or even bankruptcy in extreme cases.

So you need to know which costs to calculate, what elements are built into the costs, and how to launch a new product in a less financially risky way. Let’s get into those topics here.

Listen to the post here:

🎧 Calculating the Cash Needed to Prototype and Launch your New Product

The psychological side of launching a new product and how ambition affects a product launch.

The cost of launching a new product is related to how ambitious you are.

Making a simpler V1.0 of your product with existing modules and a modest design that doesn’t try to be cutting edge will allow you to get to market faster with a lower investment. A complex product will, naturally, be the opposite.

A lot of entrepreneurs tend to be overambitious and overoptimistic, such as applying for patents too soon, creating complex custom components, importing key components from the West to China, and launching a product that you are certain will work despite not doing any/much market research. This is a trap that will burn through your investment quickly and increase the risk of an early failure. It’s human nature to be optimistic and, in fact, new product launches require some optimism in the face of what is a hard process, but entrepreneurs also need to face reality. (09:13)

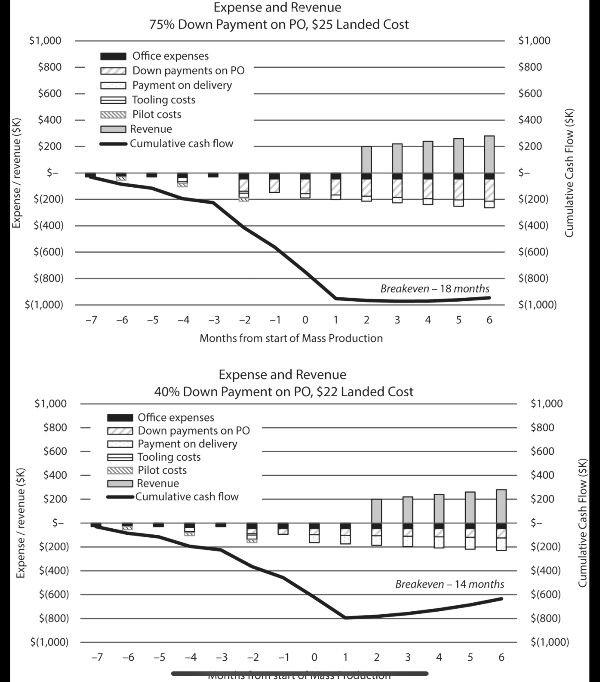

You’ll note that breaking even in manufacturing can take longer than expected, as the graphs below from the textbook “Product Realization: Going from One to One Million” show. All the more reason to temper enthusiasm with reality:

What are the finance numbers involved?

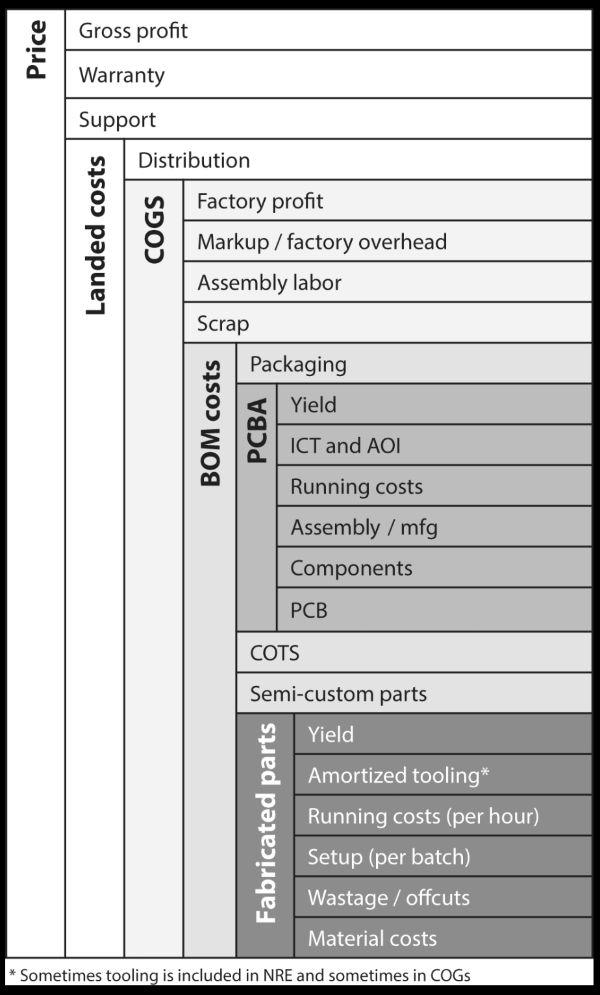

The same textbook also has a good breakdown and analysis of the financial figures involved in bringing a product to market:

The 3 calculations you’ll need to do based on the above graph to assure that the initial investment is worthwhile (because you’re going to be able to make a profit margin on finished products) are as follows:

1. What’s your investment required to be ready for manufacturing (NRE costs)? How much cash do you need to put in? This will be your own investment (unless you’ve done crowdfunding or presales) and is often referred to as NRE costs (non-recurring engineering) which is all the work you do to be ready, including tooling, certification costs, etc.

2. How much is the unit cost going to be? Take the costs of the items on the BOM, the tooling investment, assembly work, testing and inspection costs, packaging, etc, and add them together divided by the number of pieces made to get your total cost per unit out of the factory. Add the transportation costs, tariffs, import duties, warehousing, etc, to get your landed cost per unit.

3. What will the selling price be? This is how much margin you will make per product, taking into account return, warranty, after-sales costs, distribution subsidies, marketing expenses, etc.

Entrepreneurs looking for investment should note that investors will want to see a business plan including these calculations as a financial forecast. (14:46)

What’s included in these costs? (action & item breakdown)

1. NRE costs

- Engineering, mechanical, structural design, etc – who does this? In-house or outsourced? This can be very expensive for complex new products, maybe $50,000+

- Firmware

- Mobile app

- Project management

- Sourcing for components and materials

- Prototype assembly

- Testing fees, including reliability testing (more thorough testing = higher costs). The trade-off is between having a product that gets to market faster or one that is very high quality, reliability, and safety

- Tooling design and fabrication + adjustments if needed

- Special equipment such as fixtures for assembly, testing rigs, etc

- Quality engineering for setting up standards and checklists

- Process engineering for setting up the processes

- Founder’s salary

- Office and staff costs

- Shipping costs for prototypes etc

All of these should be added together to provide you with your investment cost to get to manufacturing.

2. Total landed cost per unit (production & shipping cost)

The total landed cost is made up of BOM, assembly, and logistics.

BOM: The materials, components, and packaging in the BOM. Sometimes you’ll have to pay in advance and wait for the components to be made and delivered. You may need to buy an MOQ of something that’s larger than you’d prefer, which is an investment into inventory. Your design engineers and sourcing staff should try to minimize the need for this, otherwise, it can negatively impact your cash flow.

Assembly: The assembly supplier needs to do the job and also needs to manage their suppliers, return problematic items, etc, and this adds to the overall cost (consider that there may be tens, hundreds, or even thousands of lines in the BOM with many many different sub-suppliers). A feasibility study may be required to check the costs of the key, custom, and costliest items on the BOM beforehand.

Logistics: Finally, you need to have at least a rough idea of how much getting the products to you will cost, including shipping costs, warehousing, tariffs, customs, insurance, etc.

Add up these costs and divide by how many units you have to get the TLC per unit. (22:59)

Why do many products end up being sold at a loss?

If cost estimates are incorrect, it’s easy to sell at a loss, and it would be better not to manufacture the product.

There are 2 main reasons this happens:

- Your Chinese manufacturer gives you a low quote to win your business that isn’t realistic. They later increase your costs by a lot when the real picture is revealed, such as certification costs, custom components, etc, which they may not even initially include in the quote.

- Entrepreneurs are too aggressive in their initial efforts to market and create a buzz about the product, spending money doing that and accepting initially making a lower margin which is risky if the sums are wrong and can easily result in selling at a loss. (32:39)

Other ‘hidden issues’ that don’t always show up in the calculations.

If a retailer or B2B customer only pays you after, say, 90 days, you will need to finance this.

There might be quality issues, especially if it’s a new product and/or a new manufacturer. It may cost money to inspect and fix the problems, legal fees for manufacturing agreements, flights to check on the manufacturer, etc.

Product returns and major safety issues can be very damaging as we discussed before, but it’s difficult to account for these if they’re unexpected, therefore prevention is key. (35:06)

In summary

Plan carefully, draw on the experience of others, collect typical numbers, do th work early on to get to the point where you have a fairly mature product design and most decisions have been made, and you’ll be able to get at least to a rough estimate of the costs it will take to prototype your product, develop it, and get it manufactured.

Using a staircase approach, going step-by-step, is often a good plan. Starting with a simple V1.0 with trade-offs, and then incorporating your more innovative ideas in V2.0 and 3.0 if the first one is commercially viable. (37:39)

*****

What challenges did you have when calculating your costs to get your product to market? Leave a comment, please, and contact me if you have any questions.