All importers have to pay attention to the packing & packaging elements that protect and, in some cases, add value to their product. So, let’s do a deep dive into this topic and explore packaging inspection, testing, and what is usually checked…

As a buyer, you need to specify your requirements, and you need to cover all the important points. (Otherwise, your supplier may fill in the blanks with their cheapest option.) And you need your inspectors to confirm it’s all done as per your requirements. This is the same for packaging as it is for products.

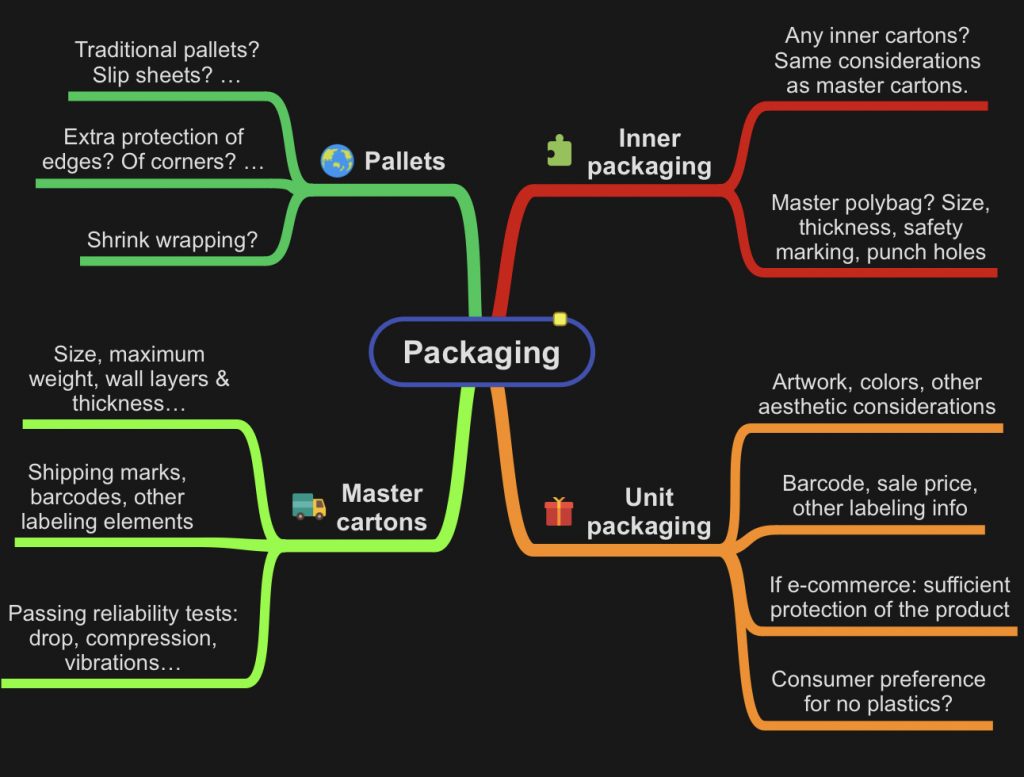

I prepared this illustration, which breaks down the most common packaging elements to check, based on our years of inspections at Sofeast.

Now let’s go through these elements one by one…

# Export packing (export cartons, pallets, etc.)

Do you want the export cartons to be fastened with clear adhesive tape, as shown below, in a “H” pattern?

Nylon bands (or other types of bands) may be necessary to make the cartons less likely to open upon impact.

What type of box do you want? A thicker wall will provide better protection, but it adds to total cost and to total volume. Here is a side view of a “double-wall” (also called “5 ply wall”). As a general rule, a “single wall” is NOT suitable for export packing.

How to test whether the cartons will protect your products? The most common packaging tests are:

- Free-fall carton drop test

- Compression test

- Vibration test

Without running any tests, it is possible to check whether all cartons are dry, in good condition, and properly stacked. This only requires a quick visual packaging inspection.

And, of course, you want to confirm that the shipping marks are as requested and are legible. You should have specified this carefully in advance: what to show on the narrow side(s) and on the longer side(s), whether you accept printed sheets of paper, whether handwriting is OK, etc.

If you want certain labels, stickers, etc. make sure to specify what they are.

Inside export boxes

Now, let’s look at the inside of those export boxes…

Should there be a protective sheet at the top and bottom?

A common issue to avoid is excessive empty space, or the opposite (excessive pressure on the products once the cartons are packed, as shown below).

And, of course, how many inner boxes, or products, are supposed to be in each carton?

Extra measures to protect export cartons

If you are afraid some boxes may get damaged, specify that they need to be plated on pallets and shrink-wrapped. They will be much less likely to drop on the floor.

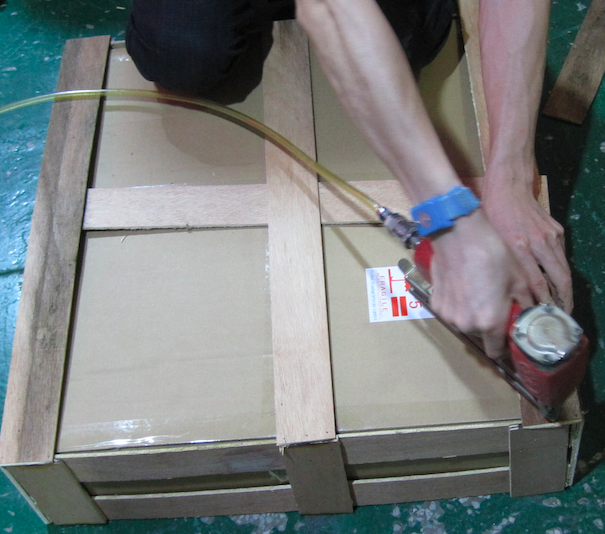

In some cases, some extra protections and straps are added:

Note: using pallets (or slip sheets, which are much thinner, to minimize volume) can reduce the time to load and unload the goods by 90% or more. It may be a great source of cost savings.

Note: using pallets (or slip sheets, which are much thinner, to minimize volume) can reduce the time to load and unload the goods by 90% or more. It may be a great source of cost savings.

When the contents are fragile, some companies add extra protection in wood:

Or in cardboard:

Or even in polystyrene:

If your products are large and valuable, full protection in MDF panels is a good option. Here is an example from the military that I saw recently on Twitter:

Notes:

- I covered all those points in How to Protect your Shipments Effectively?, and I re-used the same photos.

- Adding excessively voluminous packaging may be costing you a fortune (especially with the all-time-high price of container and air cargo space these days). As Kevin Howard wrote, “Damage problems often get the most attention, but the most costly problem is excessive packaging.” Is this the case in your supply chain?

# Inner packing

In most cases, for consumer goods, the inner packing is:

- Carton boxes, and/or

- Clear polybags

When to use boxes rather than polybags? Maybe you want to get rid of the master cartons in your distribution center and send smaller cartons to your stores. Or maybe you want extra protection for your products.

In case you have boxes inside the master boxes, many of the points I mentioned in the previous section still apply here.

In other cases, a few polybags are all that’s needed.

Important note about polybags: different countries have different regulations. The risk to avoid is when a kid put their head inside the bag and suffocates. So, if a polybag is large enough for a kid’s head, you really want to make sure there is a printed warning on the bag and some punched holes.

# Product unit packaging

For products that need to be sold in retail stores, the unit packaging is mostly designed to:

- Look good and make the product more appealing

- Protect the product’s integrity (no damages, no theft, etc…)

- Bear all the important markings such as barcodes, legal mentions, etc.

Packaging for E-commerce

More and more products need to be shipped directly to the consumer (e-commerce mode). Here are the main considerations for e-commerce packaging inspection:

- As I mentioned above, the unit packaging needs to make the product look good, it needs to protect the product’s integrity, and it has to bear certain information.

- It also needs to protect the product against shocks, compression (under other heavy packages), light rain, and other common occurrences that packages may have to face.

- If you want to ship the products by, say, FedEx, you should also check that the product in its unit packaging will fit a standard FedEx box and that the total price will not be excessively high.

Now, one way to look at this is that the product packaging is part of the product. More and more companies have made sure it stands out. (In some retail environments, the packaging can cost more than the product itself!)

The Sofeast team did a nice job a few months ago preparing a list of examples. That might be handy if you are looking for some inspiration to make your product more distinctive. See 9 Types of Packaging (Benefits, Costs, Sustainability, and more):

Conclusion

To sum up, it makes sense to focus a lot of attention on the product itself, but packaging should not be a complete afterthought. You need to specify it and confirm it will fulfil its functions by performing packaging inspection and testing.

To learn more about packaging inspection, testing, and design, explore these resources:

- How To Choose The Right Packaging To Protect Your Products? [Podcast]

- Why Packaging Is Important For Both Protection & Product Differentiation

- 4 Common Problems Importers Of Paper Products From China Suffer From

- My Supplier Didn’t Prepare My Export Packaging For Checking And More… | Disputes With Chinese Suppliers Q&A (Volume 7)