Companies that are developing a new electronic product for manufacturing in China tend to think of the way they should structure their supply chain. And they have an important decision to make. Do they choose a Contract Manufacturer buying from a PCBA factory or an EMS supplier in Shenzhen?

What’s the difference between an EMS, PCBA supplier, and Contract Manufacturer?

First, a few definitions:

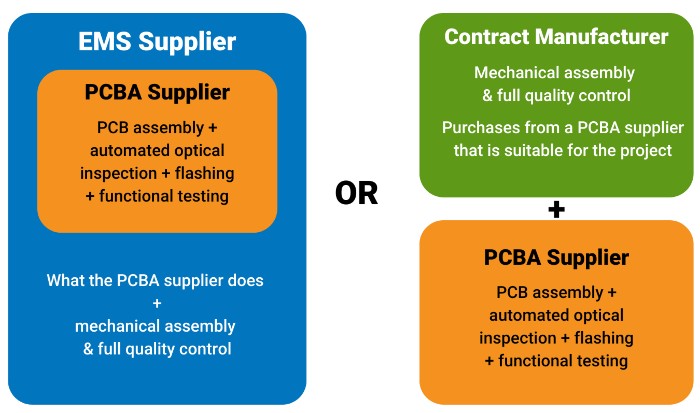

- A PCBA supplier or factory does the assembly of the OCB (printed circuit board) + AOI (automated optical inspection, among others to notice components that are not nicely placed) + flashing the firmware + functional tests. (See our videos on the SMT process if you are not familiar with it.)

- An EMS (Electronic Manufacturing Supplier) typically does the PCBA operations as I described above, and they also tend to handle the mechanical assembly + full quality control of the whole device.

- A CM (Contract Manufacturer) typically does mechanical assembly, may do a bit of soldering, and manage full quality control of the device. Typically does not do in-house PCBA work.

So, the 2 main options are:

- EMS (which does PCBA + final assembly etc.), or

- A Contract Manufacturer (CM) that works with a suitable PCBA factory.

Here is a nice way of showing those 2 options:

The EMS – the promise of getting everything done under one roof

In theory, the safest approach is to work with an EMS supplier.

In practice, though, it rarely works for small & midsize projects, for a few reasons:

- The real EMS suppliers tend to be large companies, often with thousands of workers. They focus on their few large customers, and they are not interested in projects that might generate 150,000 USD in sales if all goes very well, 2 years from now after a long development & industrialization process.

- Many PCBA suppliers market themselves as EMS suppliers. They may have a couple of SMT machines and a few assembly lines. They are not large companies and may look like a good fit. Unfortunately, they are totally unqualified for developing a new electronic device and managing its manufacturing. They don’t have expertise outside of electronics, and their people are not used to following a new product development process religiously.

The CM who works with a PCBA factory – the more realistic option for many importers

We have found that, in the vast majority of cases, working with a contract manufacturer (CM) and a PCBA supplier makes more sense.

Here is how the process of working with a CM like this usually works:

- First, pick a CM that has the right experience and capabilities, a solid NPI process, and an adequate quality system. You may want to start from the list of CMs based in China, and this advice about the ways to qualify a CM. Obviously, if you develop an electronic product, you want to work with a CM who works mostly in that space.

- Based on your project’s requirements, the CM will need to pick a suitable PCBA supplier. Some projects are high volume, some are quite price sensitive, and some need a high quality & reliability level… Not all PCBA suppliers are a good fit for all projects!!

- Your team and/or the CM’s design engineers will get the electronics and the firmware developed.

- The PCBA prototypes will be made and used in prototypes of the full product (built by the CM) until a final prototype is approved.

- A functional test rig is usually needed. It should be used to verify all the boards after the components have been assembled. And the CM should also have one such test rig, to check randomly on some boards before final assembly of the full product. This can be seen as a duplication of effort, it is also a bit of healthy cross-checking.

- The CM will think of the qualification of the suppliers of other components, reliability testing, certifications, tooling for the enclosure and/or any custom internal parts, the product quality checklist, the assembly fixtures, and so on and so forth. That’s a good part of their value added.

- When the time for mass production comes, you can decide who will flash the firmware. It could be the PCBA supplier (and the CM could be kept outside of it) or it could be the CM. It could also be a fulfilment center further down the supply chain. That’s an important decision, to prevent the uncontrolled dissemination (and potential use to compete against you) of the code.

If, down the road, there are issues with the way the SMT process was done (for example, some poor soldering that leads to reliability issues), switching to a new PCBA supplier will be possible. You should be able to make that decision.

Side notes:

- You can work with a CM to set it up the way you want. If you insist from the start to have visibility over, and direct communication access to, the PCBA supplier, it is usually no problem with most CMs.

- There are so many PCBA manufacturers in the Shenzhen-Dongguan-Huizhou area, so it is easy to find one with English-speaking salespeople. However, (very) few have experienced English-speaking engineers.

Conclusion

In the end, as I wrote again and again, you need to keep a certain level of transparency into your supply chain, and use that transparency to keep control of what happens!

What do you think? Have you been working with an EMS or Contract Manufacturer to develop and manufacture your new electronic device? What was your experience? Let me know by commenting and, as ever, feel free to reach out to me if you have any questions or need help.