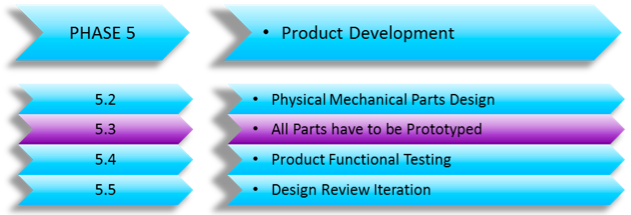

One key milestone in a new product development cycle is phase 5.3, making a prototype.

One key milestone in a new product development cycle is phase 5.3, making a prototype.

(Remember, you can see the whole series on developing a new product here).

What is a prototype?

A prototype is a representation of a design produced before the final solution exists. It allows you and potentially your future customers to understand the product. Prototype models are often used for photo shoots, trade shows and exhibitions, customer feedback, and design verification purposes.

What are the benefits of making a prototype (for your company and your customers)?

One of the crucial stages that remain part of the product development cycle involves the development of a working model which allows you to:

- Test various design features

- Verify design functionality

- Review initial product shapes or branding images

- Elicit feedback from customers or early adopters

- Use the prototype as a test-bed for developing additional features

- Identify issues as early as possible within the development stage and before going to production

- Provides a physical model for company stakeholders to review and obtain a greater understanding of the product

What are the benefits of making a prototype (for your Chinese supplier)?

The three major benefits I see are:

- Ensuring communication is clear (have they understood what you wanted?)

- Ensuring they are capable of making the prototype (sourcing the parts, putting them together, etc.) — Note that often this is possible when making a few pieces but impossible in mass production.

- Providing samples that can be used for further approvals — for example by quality inspectors when checking production before shipment in China.

Interested in this topic? You may also like Sofeast’s New Product Launch Roadmap[XLS + Video]

Our ‘new product launch roadmap’ unveils the steps that your supplier will never tell you are needed, and yet all veteran buyers consider as indispensable. Hit the button to get your copy:

Engineering and Design Benefits

From a designer’s point of view, the goal is to make a product that is not only fit for purpose within the market but also to design the product so that it can be manufactured as easily and as cost effectively as possible.

Having a prototype produced will allow the Engineering and the Design teams to review best practice techniques such as Design for Manufacture (DFM), Design for Assembly (DFA), as well as providing an excellent opportunity to carry out tests for Failure Modes and Effects Analysis (FMEA).

(Failure Modes and Effects Analysis is a step-by-step approach for identifying all possible failures in a design, a manufacturing or assembly process, or a product or service. Failures are any errors or defects, especially ones that affect the customer, and can be potential or actual.)

The Bottom Line

You almost always need to show a working model of your product idea to someone at some point. Whether it’s to potential investors to get funding, possible distribution and retail partners, or for pre-sale promotion on your website, you will invariably need some sort of physical representation of your product idea that will show viewers how it works.

When preparing for production in China, it is extremely important to get prototypes as early as possible. If the development of a new product takes too long, the manufacturer will lose interest in your project and switch his attention to the next hot product.

Go to page 9: Product Functional Testing Before China Production

Take a deep dive into the new product introduction process for hardware startups

Just starting out, or some way along the road but having a bit of trouble? Sofeast’s guide covers everything hardware startups need to know for making a new product in China and successfully bringing it to market.

Hit the button below to read the guide: