From my observations, procurement offices and trading companies that are based in China tend to make the same mistakes. In this article I will explain how they should be organized.

From my observations, procurement offices and trading companies that are based in China tend to make the same mistakes. In this article I will explain how they should be organized.

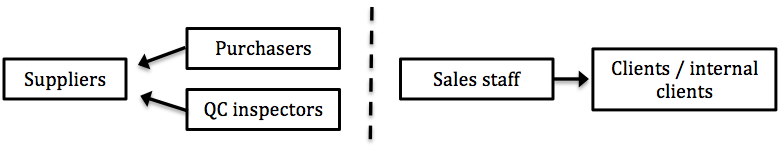

The traditional organization

- Some purchasers face the suppliers;

- Some English-speaking salespeople face customers (or their head office).

Apart from a few managers, no one knows the buying AND the selling price. It is the whole point of cutting the organization in two.

Downsides of the traditional organization

- The organization is composed of specialists, each group working in its own functional siloes. It means communication is difficult.

- Nobody who is responsible for a supplier’s overall behavior (reliable quality, respect of timing, no last-minute price increases…).

- The purchasers’ work is insufficiently supervised, and kickbacks are common.

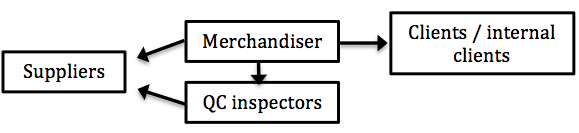

A better buying organization

- A team of 1-3 merchandiser (the word means different things in different industries, but bear with me) manages some orders.

- A few inspectors work ONLY on that team’s orders.

- Merchandisers spend 1-2 days a week in factories, together with inspectors.

Advantages of this organization

- The team leader has ownership over the supplier’s relationship, and is more likely to exert pressure when necessary.

- When an inspector reports that the factory is rushing production, and when the customer is flexible with dates, the team leader can decide to ask the supplier to proceed at a normal pace and to ensure quality is satisfactory.

- Communication is much easier and faster.

- Every decision is taken in a more open manner, and kickbacks become less common.

- The staff is more flexible. Merchandisers can help check quality when too many shipments are ready at once and inspectors can’t follow that schedule.

- Hopefully these small teams can self-manage after some time, rather than constantly asking the boss for small decisions.

Note that an even better organization would gather these merchandisers and inspectors with designers and engineers. I wrote why a few months ago.

—

I’d be curious to hear from readers who have experience with one of these types of organizations!

This is a great explanation, diagram and post, Renaud. Most overseas buyers don’t have the faintest clue of how little importance their order holds with the overall organization of their supplier or factory. Since departments are so chopped up, info is not shared, like you said above,

the sales person who handles a buyer, doesn’t have any sway inside of

the factory.

Although a buyer may jump up and down and inform the sales person of many issues, only a slight percentage of the buyers’ concerns reach the production floor.

Also pricing: the sales departments don’t stay in touch with production or purchasers and that’s one of the main reasons that buyers see sudden changes in pricing, even after the official quotation.

The person who cares the most about the buyers’ business is that direct sales contact, but how much control or authority do they have for their care to turn in to real results?

Your “better buying organization” is very team-oriented, would work, and I think initially it would take much time and training for the employees in China to learn. They are not accustomed to team-oriented atmospheres and watching each others’ backs… but with the time and purpose and right folks..it can happen.

I learned a lot from this one, Renaud, thanks my friend.

Thanks for adding to the post, Jacob. Glad to see that you like this idea.

This kind of organization already exists in some companies here. And it works.

Break down departmental barriers and work as a team: that’s the application of “lean thinking” to the office!