Many buying offices in China struggle to have their QC inspectors (trained to assess conformity to a set of requirements) act as QA technicians (able to analyze problems and solve them). What type of training is appropriate?

Many buying offices in China struggle to have their QC inspectors (trained to assess conformity to a set of requirements) act as QA technicians (able to analyze problems and solve them). What type of training is appropriate?

I think the 7 basic quality tools are very appropriate. They are easy to teach and to use. According to Dr Ishikawa, these tools can help solve 95% of quality problems that are encountered in daily operations!

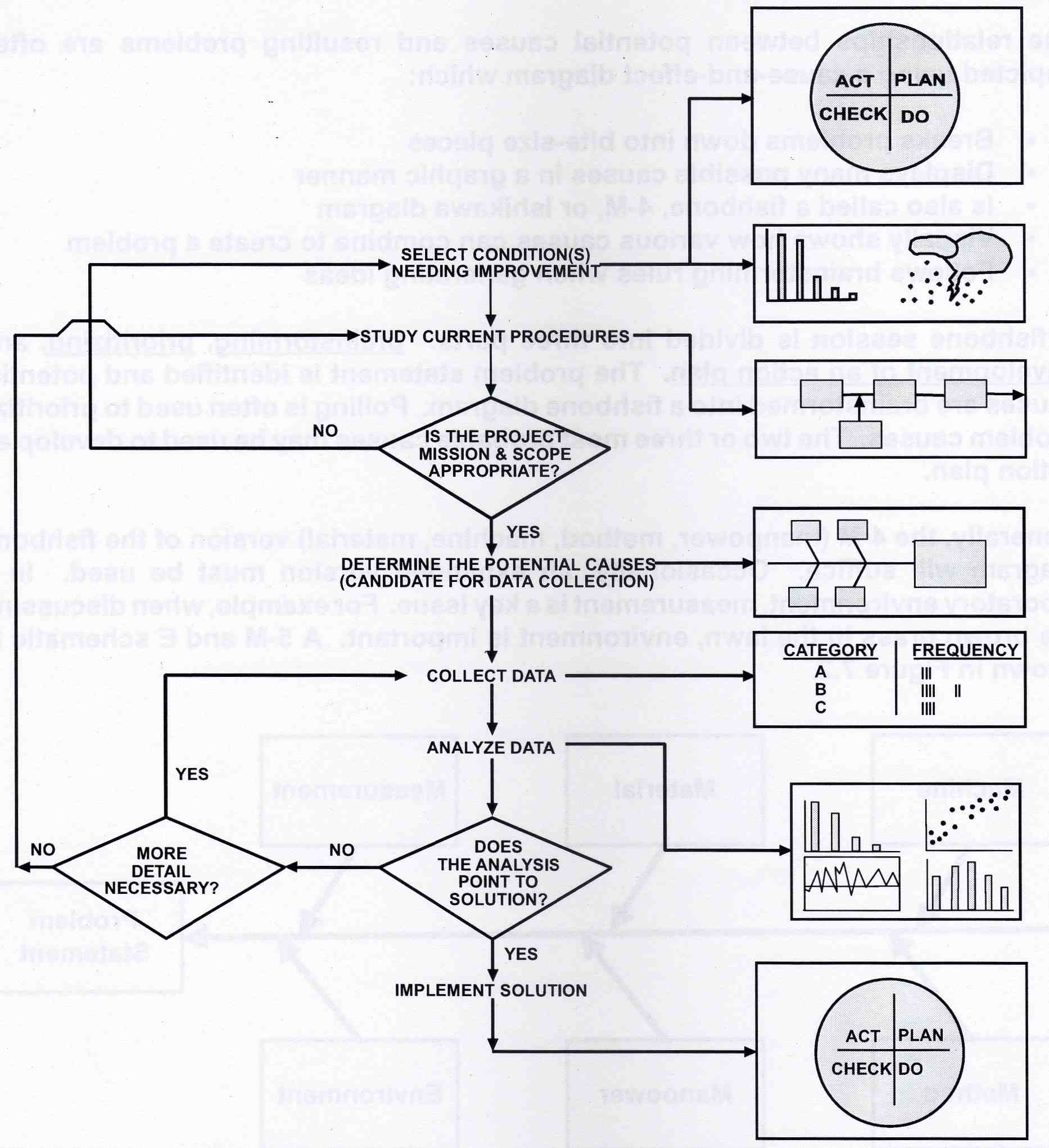

The question is, how to integrate these tools in a problem resolution method that follows the PDCA (Plan-Do-Check-Act) logic?

I found a simple explanation (see below graph) that puts it all together:

PLAN

- Data collection to select an improvement project: use Pareto charts and/or scatter diagrams

- Study of current procedures: flow chart

- Thinking of potential causes: cause-and-effect diagram (or fishbone diagram)

- Data collection on potential causes: check sheet

- Data analysis: control charts, histograms, Pareto charts, and/or scatter diagrams

DO

(No need to use these tools)

CHECK

- Data collection: check sheet, control charts

- Data analysis to see if there is improvement: control charts, histograms, and/or scatter diagrams

ACT

(No need to use these tools)

Source: Primer for CQE exam, published by the Quality Council of Indiana.

Source: Primer for CQE exam, published by the Quality Council of Indiana.