The French Chamber of Commerce organizes the Made In Asia conference every year. I missed last year’s edition, but I attended this year. The theme was transparency in sourcing.

Here are my notes.

What drives transparency in the supply chains?

A speaker from Puma pointed to these 4 major forces:

- Consumer safety regulations such as REACH.

- Bad press, or the risk of bad press — show the reality to avoid wrong accusations or over-generalizations

- Social media — a different beast from the press, and even faster

- Working closer with suppliers to co-create new styles and gain speed

A speaker from H&M (a pioneer in showing their tier-1 and tier-2 supplier list on their website) insisted that transparency builds trust. He gave three examples I liked.

- A number of large brands & importers have joined the Sustainable Apparel Coalition, which gives factories a grade. This can be shown all the way down to the consumer in a store.

- H&M’s brand Arket shows where each product was made. Example below.

- A Chinese supplier decided to collect real-time data about their water consumption, air emissions, etc. and shows it on a large screen in front of their factory. Wow!

Are some retailers actually driving changes?

In the examples above, the retailers and brands push the manufacturers to “open up” and to comply with international standards and local regulations. And, on the whole, my impression is that it is pretty slow.

There are a few exceptions, though, and Ikea is probably the best illustration. A speaker from Ikea shared 4 ways they help improve the situation:

- They work hard at helping their suppliers reduce scrapped materials and rework. In itself, that ‘saves’ thousands of tons of good material. A big win for the environment.

- They help improve efficiency so that a factory can pay the same amount to workers while ensuring they work fewer hours.

- They try to find ways to make families live together, so that kids don’t need to be sent to the home town to be taken care of by a grand mother. This reduces staff turnover in the factories.

- They request traceability on raw materials and find ways to make those materials’ production more efficient — for example, improve they way to grow cotton.

And what are leading manufacturers doing?

A speaker from Hasbro, the toy company, pointed out that stricter regulations are pushing manufacturers to consolidate in some industries. Larger companies can comply with new standards more easily. “It takes 1 million USD in sales just to pay for compliance, let alone for the fees themselves.”

A speaker from Crystal Int’l Group, which might be the largest apparel manufacturer in the world, with sales of 1.7 billion USD and sites in 5 Asian countries, shared their efforts with compliance.

One of the interesting things they did was focus on engaging with their workforce and avoiding miscommunication.

Some of the approaches are classic: training, birthday celebrations, classes about anything of interest to the staff, meetings with work representatives, suggestion boxes, helping the community, etc.

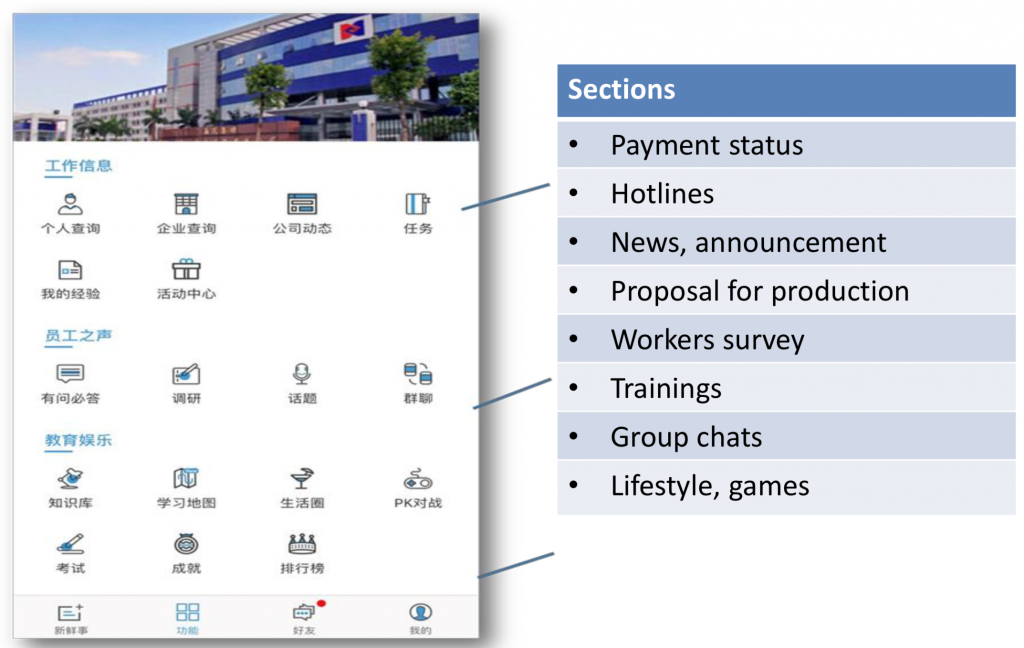

They did one thing that seems to be working really well. They noticed that nearly all their employees had a smartphone, so they developed a mobile app for them. Here is what it contains:

Is transparency enough?

Obviously, it is not, as a speaker from Liberty Asia noted. “Transparency is not accountability.”

There are about 25 million slave laborers in Asia. How many of them are involved, at one level or another, in products that end up in stores in Western Europe or in North America? Probably many.

Regulations are getting tougher across the globe and are pushing for more transparency in global supply chains. The toughest regulation is in France.

Consumers are also pushing for more transparency, as they suspect brands of not telling the truth about the conditions in which their garments, shoes, etc. were made.