Vetting suppliers is important. After all, these suppliers are responsible for your company’s reputation.

Hopefully, everyone by now will understand the dangers of checking Alibaba or Global Sources and ‘choosing’ a supplier who ‘looks’ good, or perhaps trusting that Alibaba Gold suppliers are somehow more legitimate and trustworthy (spoiler alert: they might not be). So what does a good vetting process look like?

Starting the relationship off the right way

The supplier selection process necessarily has to be more involved than an online search and placing an order, to get great results and end up with a sustainable, safe, relationship. That’s why we’ve created a podcast series (on the Sofeast podcast ‘China Manufacturing Decoded‘) on this topic. Hit the links below to listen to the episodes…

1. 7 Ways Suppliers Can Cheat Importers Or Cause Problems

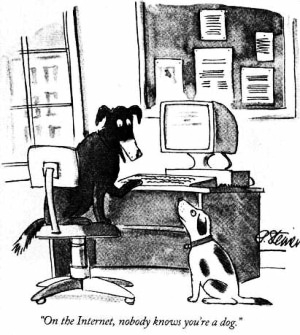

As this humorous picture shows, you can never be sure who you’re dealing with over the internet…

So, in this episode of the podcast, I kick off the process of vetting suppliers in China right at the very beginning of your journey: Understanding the risks and ways in which Chinese suppliers can scam you.

There are 7 ways that you can get into trouble with Chinese suppliers, 5 being bad behaviors and 2 from typical lack of competency. Consider yourself cheated if they:

- Take your deposit or wired payment and disappear

- Increase the price once you’ve already paid to start the project but haven’t received anything yet (holding you to ransom)

- Raise prices between orders unexpectedly

- Steal or use your IP (product designs etc) without your permission

- Keep you in the dark about subcontracting your work and other nasties

- Are unreliable

- Can’t or won’t reach your quality standard

Now you know some of the major red flags to look out for when sourcing Chinese suppliers.

2. Initial Vetting Process & Approaches To Weed Out ‘Bad’ Suppliers

Now that you know what you don’t want from a supplier (see above), what are some of the first steps you can take to weed out suppliers who aren’t suitable?

The initial vetting process is outlined here:

Getting started by finding companies who seem suitable can start online with no need for you to be in China at all, but, as mentioned, their online claims should be taken with a large dose of salt at first.

You should follow the tips we discuss to start assessing that they and their capabilities are right for you.

This will include:

- Checking that their online profiles are consistent

- Finding out if they have any bad online reviews or news stories

- Examining their business license and listing on the Chinese government database (you may need help for this as information is in Chinese)

- Getting references

- Taking copies of their certifications and checking them with the issuing bodies (such as ISO 9001)

- …and more

This is fact-finding that you can do remotely before even considering placing an order. Also, factory audits and due diligence checks will achieve the same results for you if you’re unable to go to China (such as during the coronavirus pandemic).

3. How To Evaluate Your Supplier’s Engineering Capability

Next, we focus on why and how to evaluate your potential Chinese supplier’s product engineering capabilities.

This is especially important if you’re working on new product development and manufacturing with the supplier because you’re likely going to rely on their manufacturing expertise quite a lot to get your product to market.

We mainly concentrate on the 5 key engineering attributes you need to check:

- CAD Compatibility

- In-house Design Capability

- R&D Facilities and Capability

- Prototyping Capability

- Initial Prototype Test Capability

By gaining an understanding of the above, you can decide whether the supplier has the engineering experience, knowledge, and capability to design and develop your new products before you start working with them.

4. On-site, Subjective Factory Evaluations

Up to now, all of the information discussed can be gained remotely, but a traditional factory visit also provides a lot of value.

If you’ve now made a shortlist of suppliers or are confident that one is a good fit, now is the time to visit their facility.

What can you see? How do management and staff behave? Does what you’re seeing equate to the information you found when vetting them in earlier steps (for example, does their facility have the equipment they claimed to have online or in emails to you)?

All of these observations help you to fact-check what you thought you knew about the supplier and also speaks volumes about their professionalism and management.

Did you know that even by checking the operators’ toilets you can learn something about employee welfare!?

However, your potential supplier won’t always be willing to just volunteer information, so you’ve got to know what to look for and why before your visit and, to help you, we’ve prepared a number of factors to consider based on these three categories:

- Factory fit

- Factory management

- Factory setup and condition

5. The Importance Of On-Site Factory Quality Audits

Now that you have done a preliminary investigation into your potential new Chinese supplier and perhaps even visited their factory to do a subjective evaluation, the next step in the vetting process is to perform a factory quality audit.

Understanding your manufacturer’s grasp of quality and in-house quality systems means that you’re able to assess whether they’re going to be able to fulfil your quality needs down the line. Even if they’re a legitimate company, this doesn’t mean that they’re able to produce your goods at the quality you need.

This episode includes:

- What the different factory audits are

- Standards like ISO 9001

- Exploring quality systems and why they need to be audited

- What a factory auditor does when on site

- The top 8 checkpoints to focus on in a factory audit

6. Why Conduct On-Site Social Compliance Audits?

Ideally, using a social compliance audit to assure that your supply chain is free from illegal practices such as modern slavery is an important factor in vetting and working with a new supplier.

Fundamentally, a social compliance audit protects you from being associated with things in your supply chain which could damage your company or brand, but they do have drawbacks, too.

We’ll discuss:

- Some examples of the 3 ‘big’ circumstances that importers want to avoid: Child labor, forced labor, and dangerous working conditions.

- Does improving working conditions for staff increase the prices you’re likely to pay?

- Elements of SC audits that probably aren’t as important as you may think.

- The smart selective approach to conducting these audits.

- Issues with lying and corruption in this field of auditing.

7. Exploring Process Audits

We’ve already discussed quality audits and social compliance audits, and this time we’re going to cover factory process & system audits. While this type of audit may not differ too much in terms of structure (an auditor still goes into the factory observes, questions staff, and takes notes), this time we’re checking the maturity of the factory’s systems and process controls with the objective of assessing how reliable they are, if they’ve put thought into how they manufacture, if they follow best practices, and, therefore, if they’re going to be capable of fulfilling your expectations in the longer term.

As a part of the supplier vetting process, process audits give great insight into whether you’re selecting a supplier who can fulfill their promises to you.

Here are some of the key points we go over:

- What process audits are

- What kinds of businesses will benefit from performing process audits?

- High-risk products

- A list of what is usually checked in a process audit

- Outline of a process audit checklist

8. Factory Testing Facilities

In this episode, we’re discussing factory testing facilities and how they can help you to assess how capable a supplier is. Ask the question: “How can this supplier know that their product is good if they’re unable to test that products reach my specifications, quality, and safety requirements?”

It’s important for you or your auditor to assess a potential supplier’s testing facilities as their professionalism in testing speaks for their overall ability and quality-consciousness.

You’ll hear about:

- Why pay attention to testing being done in the factory by the supplier

- Checking testing equipment tells you a lot

- If a supplier conducts testing and provides some kind of report this is a positive sign

- Some examples of testing for different types of products and some key observations about what suppliers may or may not do

- Is it helpful to have a supplier’s test reports in hand when you go to a laboratory to conduct your own tests on the product samples?

- The risks of ‘buying cheap stuff from China’ without understanding your liabilities as an importer and what kind of testing is required

9. How To Perform In-Depth Due Diligence On Your Supplier

Many importers aren’t able to travel to China (or other Asian countries) to check on their new or current suppliers’ progress, so getting an understanding of how their business is doing and if they’re engaging in any practices which could cause risks for your supply chain has become more difficult. Nonetheless, understanding how and why to perform in-depth due diligence is an important step to assuring supply chain stability and quality for those of us who can’t visit China yet, and as a standard part of your vetting process to stamp out risks.

We explore:

- Why due diligence while sourcing is more important than ever

- A list of key points to focus on

- The serious risks you need to investigate when examining a potential supplier

- Is developing a backup supplier worthwhile in case problems are found with your first choice?

10. Pricing, Negotiation, Contracts

If you have selected a shortlist of possible suppliers and are now ready to ask them for quotations there is still quite a lot you can learn about them at this point of the sourcing process.

Here are the tips we share:

- When is the right time to start asking for quotations

- How to keep IP secure at this point

- Mistakes buyers make when requesting quotations from Chinese suppliers

- Why doing product design and prototyping outside of China/Vietnam etc is a good way to protect IP and streamline the vetting process

- How buyers need to be very clear when communicating requirements in order to help suppliers give them a solid quotation

11. Tips For Continually Getting Good Results From A New Supplier

In this series of episodes, you will already have learnt about due diligence, factory audits and visits, exploring testing facilities, and much more when it comes to vetting suppliers. But how do you carry on getting the results you expect from your new supplier once you have been working together for a while?

We discuss some of the common scenarios you may face in your new relationship, such as needing to switch from an underperforming supplier to a new one or facing an unexpected price rise, and what you can do to combat or overcome them:

- Why developing a backup supplier is a wise move

- When to switch to a new/backup supplier if things are going wrong with your current one?

- Dealing with unexpected price rises

- Developing suppliers based on their quality performance data

- Tracking supplier performance and reviewing it over time

You may also like this blog post: 7 Reasons To Switch To A New Chinese Manufacturer

This explains why you may wish to switch to a new supplier or develop a backup, especially if it turns out that you have been working with a current supplier who hasn’t reached your expectations (for instance for quality, delivery times, cost, etc).

Subscribe to the podcast

There are more episodes to come, so remember to subscribe! You can do so in your favorite podcast apps here:

- Apple Podcasts

- Stitcher

- Spotify

- TuneIn

- The podcast’s website at China Manufacturing Decoded

Are you trying to find a manufacturer in China who is well-suited to your needs and can also deliver on their promises?

Sofeast has developed 10 verification steps to help importers find the right manufacturing partner in China. They’re shared in this FREE eBook: “How To Find A Manufacturer In China: 10 Verification Steps.”

It covers:

- Background checks

- Manufacturing capabilities

- Quality system auditing

- Engineering resources

- Pricing, negotiation, & contracts

- …and much, much more

Just hit the button below to get your copy and put yourself in a great position to get better results from Chinese manufacturers who supply your products:

![Vetting Suppliers In China [Podcast Series] Vetting Suppliers In China [Podcast Series]](https://qualityinspection.org/wp-content/uploads/2020/07/VettingSuppliersInChinaPodcastSeries-1024x538.jpg)