I was thinking of the most common problems Chinese suppliers cause for importers, especially those developing their own products.

And I noticed something interesting. Most of them all linked to the way information is managed.

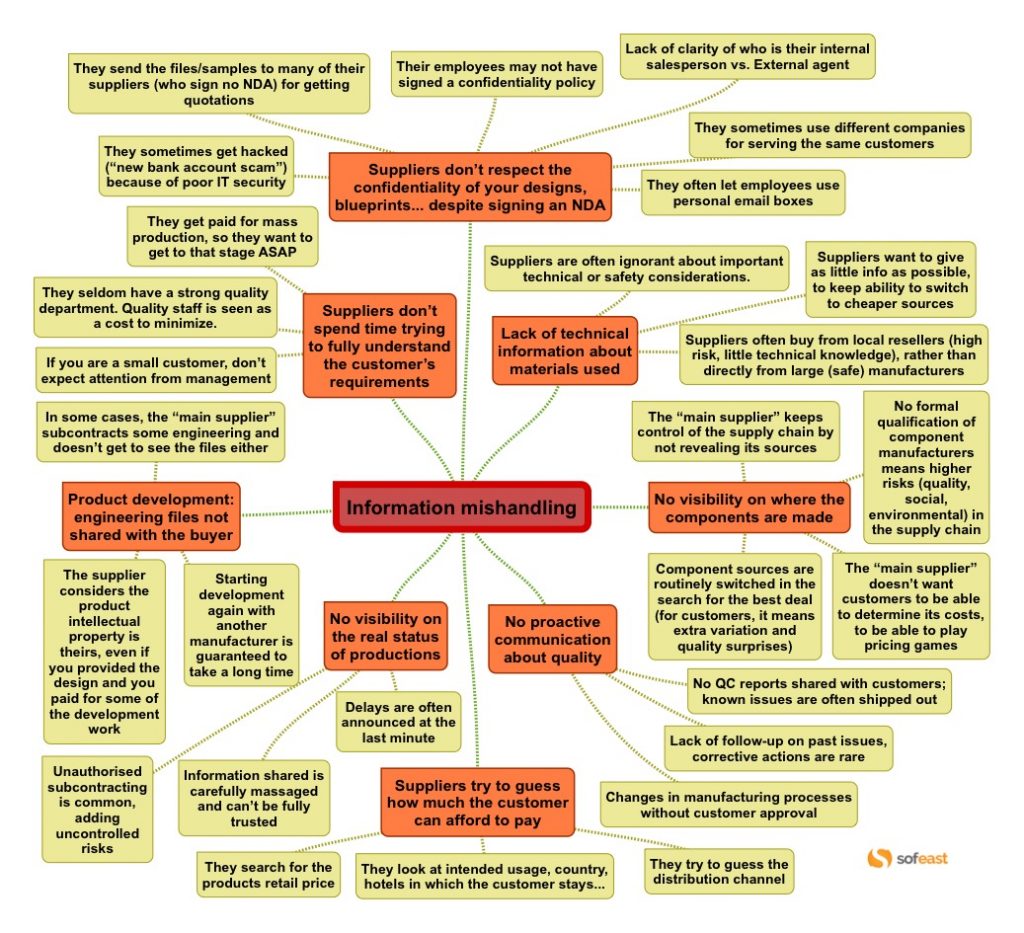

A mind map showing the problems caused by Chinese suppliers that are linked to information mishandling

I drew this mind map to show how it often plays out:

A few important notes:

- There are other serious issues that come from other root causes (no concept of proper quality management, no idea about the need for pre-production prep work, etc.). And these issues often originate from both sides, not just from the buyer’s side.

- Some China-based manufacturers are superb in their understanding, their execution, and their general behavior. What I drew here applies to about 90% of local suppliers.

28 problems for importers to be aware of

Here is my list of the 28 problems split into categories:

# Suppliers don’t respect the confidentiality of your designs, blueprints… despite signing an NDA

1. They send the files/samples to many of their suppliers (who typically sign no NDA) for getting quotations

2. Their employees may not have signed a confidential policy

3. They often let employees use personal email boxes

4. Lack of clarity of who is their internal salesperson vs. external agent

5. They sometimes get hacked (“new bank account scam”) because of poor IT security

6. They sometimes use different companies for serving the same customers

# Suppliers don’t spend time trying to fully understand the customer’s requirements

7. If you are a small customer, don’t expect attention from management

8. They seldom have a strong quality department. Quality staff is seen as a cost to minimize. It is the salesperson’s job to understand your requirements, but that person is usually not trained to do that.

9. They get paid for mass production, so they want to get to that stage ASAP

# Product development: engineering files not shared with the buyer

10. The supplier considers the product intellectual property is theirs, even if you provided the design and you paid for some of the development work

11. Starting development again with another manufacturer is guaranteed to take a long time since you need to start from scratch

12. In some cases, the “main supplier” subcontracts some engineering and doesn’t get to see the files (e.g. source code, PCBA schematics, CAD files…) either

# No visibility on the real status of productions

13. Unauthorised subcontracting is common, adding uncontrolled risks

14. Information shared with buyers is carefully massaged and can’t be fully trusted — on-site visits are often necessary to know what is going on

15. Delays are often announced at the last minute

# Suppliers try to guess how much the customer can afford to pay, in order to charge as much as possible

16. They search for the product’s retail price

17. They look at intended usage, country, hotels in which the customer stays…

18. They try to guess the distribution channel

# No proactive communication about quality

19. No QC reports shared with customers; known issues are often shipped out anyway

20. Changes in manufacturing processes without customer approval

21. Lack of follow-up on past issues; real and effective corrective actions are rare

# No visibility on where the components come from, how much they cost, etc.

22. Component sources are routinely switched in the search for the best deal (for customers, it means extra variation and quality surprises)

23. The “main supplier” doesn’t want customers to be able to determine its costs, so they can play pricing games

24. No formal qualification of component manufacturers means higher risks (quality, social, environmental) in the supply chain

25. The “main supplier” keeps control of the supply chain by not revealing its sources

# Lack of technical information about materials used

26. Suppliers are often ignorant of important technical or safety considerations.

27. Suppliers want to give as little info as possible, to keep their ability to switch to cheaper sources, and to prevent customers to know what to test for

28. Suppliers often buy from local resellers (high risk, little technical knowledge), rather than directly from large (safer) manufacturers

***

Have you experienced any of these problems Chinese suppliers cause? How did they affect your business, and how did you overcome them?

Do you have any extra ideas to add that I might have missed?

Please leave a comment or question and let me know!

Are you wondering how to find a manufacturer in China who is well-suited to your needs and can also deliver on their promises?

Sofeast has developed 10 verification steps to help you find the right manufacturer. They’re shared in this FREE eBook: “How To Find A Manufacturer In China: 10 Verification Steps.”

It covers:

- Background checks

- Manufacturing capabilities

- Quality system auditing

- Engineering resources

- Pricing, negotiation, & contracts

- …and much, much more

Just hit the button below to get your copy: