Setting clear quality standards for each type of product you purchase in Asia is a basic need. Like in “to keep living, breathing is a basic need”.

Despite this, very few companies that have production in China or Vietnam take the time to do it right. And, as a result, they have to suffer quality issues, misunderstandings, and the breakdown of trust with their suppliers.

Let’s go through the 5 levels of quality standards, from most basic to most advanced.

1. The golden sample

Most importers, even the least experienced ones, tend to know that a physical “standard” is always needed before approving production launch:

- For garments and other textile products, it is usually a pre-production sample made with ‘exact fabric and accessories, available colors’, together with fabric swatches in the exact color or simply a TPX Pantone code.

- For an electro-mechanical product developed from scratch, it is usually the ‘work alike and looks alike’ prototype, and if possible the pre-production prototype made with components that were made with the custom tooling and with the approved surface finishing (e.g. plating).

The ‘golden sample’ is a must to confirm the touch & feel and the general appearance of production. It is often marked or sealed in a permanent manner, for easy identification and also to prevent swapping.

Make sure your manufacturer and your external QA staff also have an approved golden sample in their hands.

A serious limitation of this often-called ‘golden sample’ is its inability to communicate what level of variation is acceptable. Many buyers address this issue by documenting tolerances in written form — see next section.

2. The master specification sheet + BOM

A written specification sheet, or checklist, is also an important part of the overall “quality standard”.

If the product length has to be 20.5 cm, is 20.1 cm acceptable? Make sure this is clear to all parties by documenting your tolerances (e.g. +/- 0.2 cm).

Many things can be quantified. For example, if a painted part has to be very very close to the specified color, you may specify “delta E of color must be less than 2”. This is not even noticeable to the naked eye!

I suggested a template for this document before. And I suggested some good practices that help prevent misunderstandings and increase the level of commitment from the manufacturer:

- Think of the QC inspection and testing process when writing this document. It means you will include tolerances, descriptions of potential defects, and so on.

- Have someone translate it if you don’t fully trust the supplier’s salesperson to do so.

- Get a factory manager to comment on it, and adapt it if necessary. Two-way communication is very important.

- Ask the supplier to date, sign, and stamp it to indicate their acceptance of your specifications.

It may also include:

- A test plan (for electro-mechanical products)

- 2D drawings with tolerances and indications of what dimensions are critical

- The user manual and any claims written on the packaging

And, of course, don’t forget the packaging. I wrote before about ways to protect your shipment.

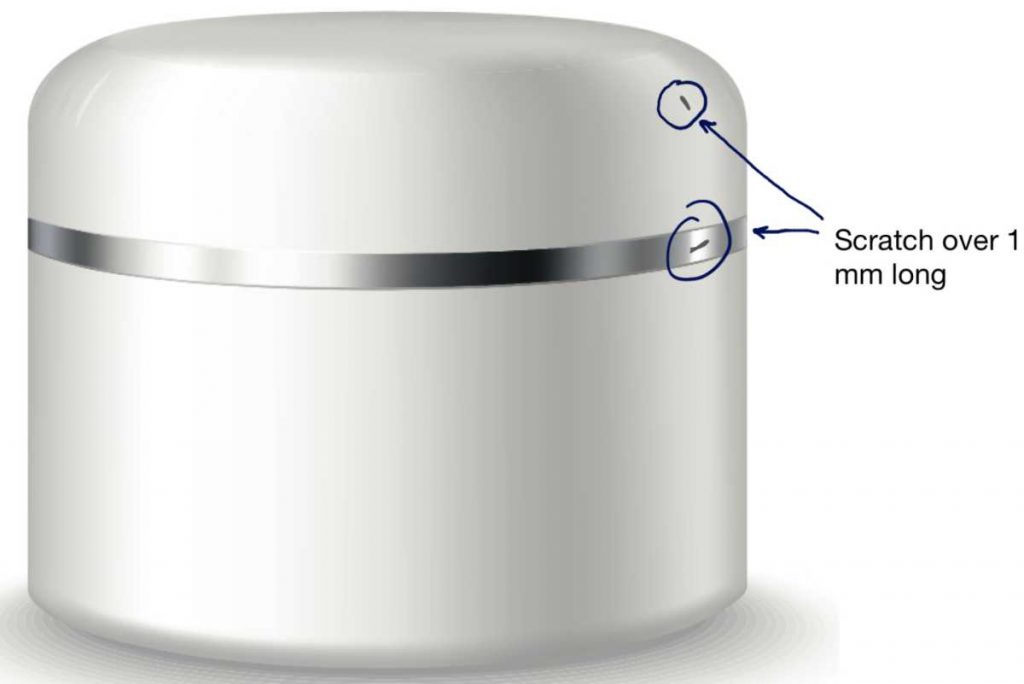

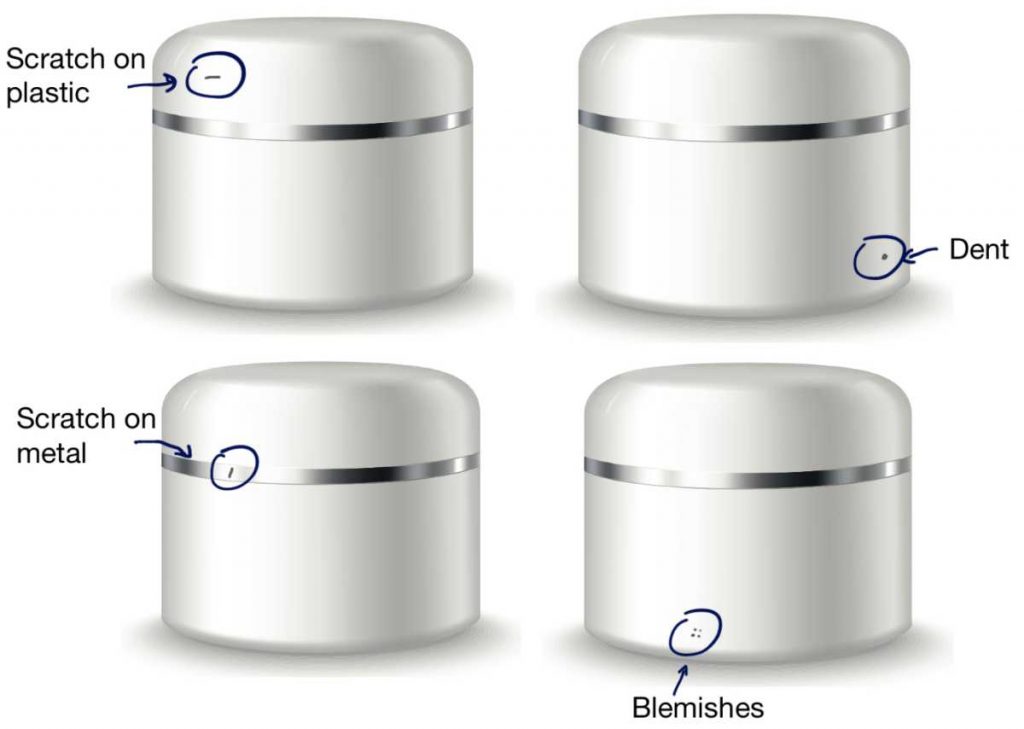

When it comes to appearance, think of the defects that are most likely to come up and point them out (We wrote examples on mechanical products, for example.):

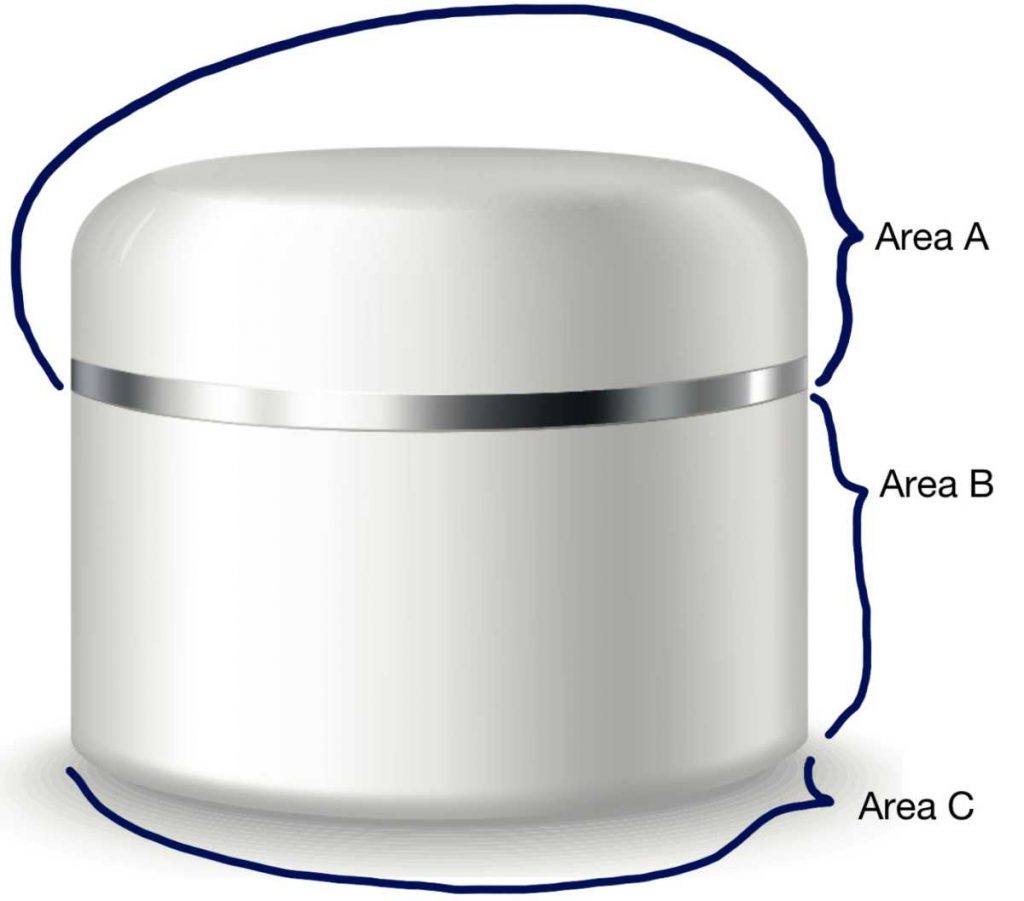

Many companies divide their products into areas A, B, and C. They typically want only imperceptible imperfections on area A, while they can accept visible defects on area C:

Once all this is documented, it can be mentioned in a purchase contract, too. It is often the most important element you want your supplier to commit to. It is worth spending time to get it right!

Once you have a golden sample and specification sheet, you have the basics to set up your own basic QA system, as described in this (25 min) video.

I also mention the BOM (Bill Of Materials) in the title of this section. I described what the BOM is before. That’s a crucial element, but many importers struggle to gather this information because their OEM/ODM supplier is not transparent about it.

Ideally, you will be able to specify:

- What exact materials (including their nature and exact chemical designation), from what source, are to be used

- What exact components (including their specifications and, if applicable, MSDS), from what manufacturer, are to be used

- A way to check each of them, be it by checking the markings, by burning the plastic, by conducting tests, etc.

3. The defect board

How to make sure production operators and quality inspectors, at the factory level, know what is acceptable and what is not?

Writing description of defects, or collecting photos, does help. But nothing beats physical samples shown on shelves, next to an assembly line!

The key is to collect a few samples that display some of the most common types of defects in a defect board as shown below:

If the product comes in several colors, make sure to take that into account. The same issue might be much more visible on one color, for example.

This is very helpful, as it is a great way to train the people who really need to comply with your quality standards.

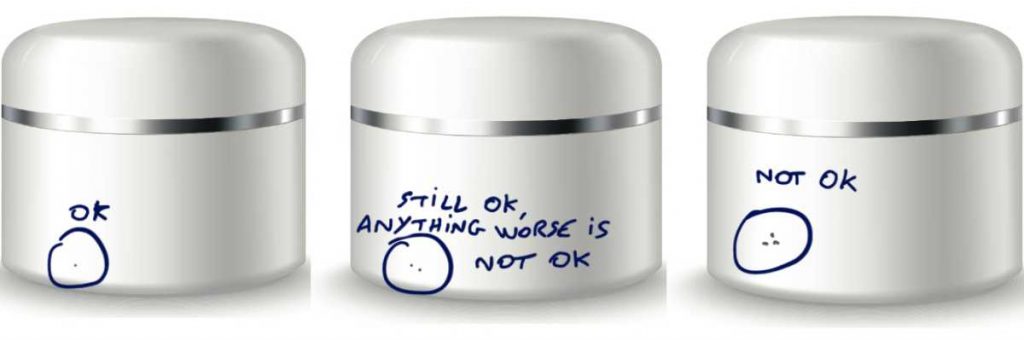

4. The boundary samples

I got sick of hearing Chinese manufacturers say “but you know it can’t all be perfect, everyone knows that”. The simple answer is ‘let’s clarify exactly what is acceptable and what is not’.

If a pilot run took place on custom components and/or on assembly, chances are there are many defective samples to use to illustrate the boundaries of what is acceptable.

Here is a simple example:

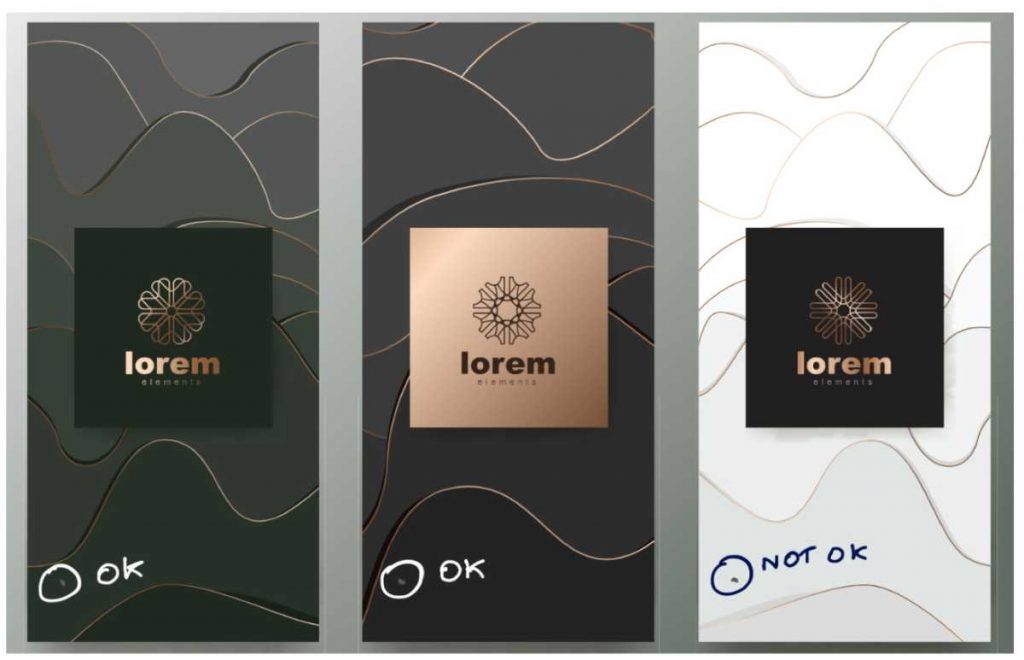

This approach is very common to clarify what range of colors is applicable. The buyer would approve:

- A ‘golden sample’ – exactly the color desired

- A variation that is a bit lighter

- Another variation that is a bit darker

As with all the physical samples I described above, a few ‘good practices’ are important:

- Colors fade fast, and surfaces get dirty. A common approach is to keep samples in clear bags and renew them every 6 months.

- The buyer needs a set of samples. The supplier, too. The component suppliers, the printer, the anodizer, etc., too. External inspectors do, too.

- Training the people and checking they can apply it is always necessary. Don’t rely on documents alone.

- In many cases, 1 person at the factory is trained in more depth and is tasked with training other people there.

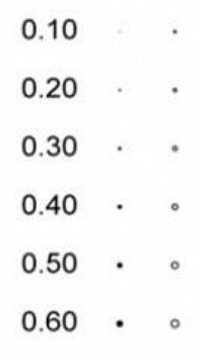

If collecting and categorizing boundary samples is not possible, you need to find another way to clarify your requirements. For example, this type of card can be purchased online easily. Suppliers and inspectors will understand “imperfections >0.40 mm” much better if they have this in hand.

5. Going deeper: Confirming the inspection system

All the documentation in the world won’t ensure all the parties using that common documentation will draw the same conclusions.

How to double-check on that aspect? By conducting a gauge repeatability & reproducibility study (GR&R) that involves several inspectors and the same set of samples, including in the manufacturing facility and on the importer’s side.

A GR&R can be done:

- On variable data — for example, the measurement value found with a measurement tape.

- On attribute data — for example, whether a certain sample counted as defective or not.

Conclusion

Nothing in this article is new. We have had the chance to work with companies that did a wonderful job setting their quality standards, but also many other companies that didn’t even try to create a common understanding with their suppliers.

If you keep buying similar products, or if you develop and manufacture a few unique designs, make this one-time effort for each category and it will keep paying dividends for years to come.

Get expert help to improve YOUR product quality from suppliers in China or Vietnam. Read: Quality Assurance In China Or Vietnam For Beginners

Grab your free copy of Sofeast’s eBook and learn the common traps new importers from China or Vietnam fall into, and how to avoid or overcome them in order to get the best possible production results. It also outlines a proven quality assurance strategy that you can follow in order to have better control over your product quality, covering:

- Finding Suitable Suppliers

- Defining your Requirements before Production Starts

- Don’t Skip the New Product Introduction Process

- Regular Quality Inspections (Trust but Verify)

- Tying Payments to Quality Approvals

Sounds good? Hit the button below to get your copy now: