I’ll assume you have found and audited a good manufacturer. They have communicated well up until now, and you feel confident about them.

But should you feel confident? Several things can go wrong:

- They might be too busy and farm your job out to another factory – without telling you.

- They might receive substandard components from their suppliers, and decide to use them anyway.

- Your product might be new to them in a way you did not anticipate or forecast.

Fortunately, there is a simple solution: send an inspector into the factory during production. If you work with a quality assurance agency, it should cost you about 300 USD per visit.

1. When to send an inspector during production?

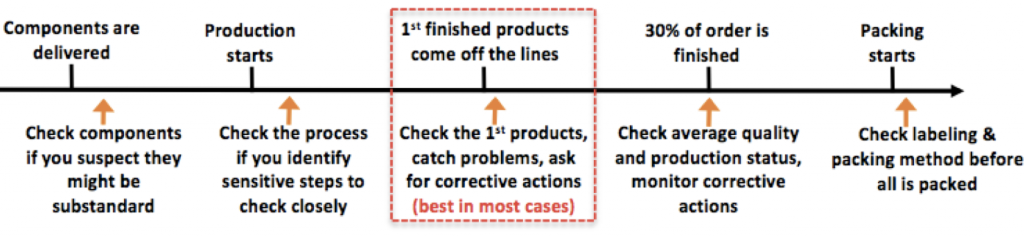

It depends on the risks you want to mitigate; different options are shown below:

Let’s look at the most common cases, one by one.

a) You are not sure. The best, in most cases, is to come 1-2 days after the 1st products come off the production lines.

From experience, this is the timing I generally recommend for consumer goods, but not for technical/industrial goods (see note below).

b) You are afraid the components are wrong but will be used in production anyway (not a rare situation in China). You should come once all the components have been received but before production starts. You really don’t want substandard components to be embedded in your products. After that, the only solution is often to re-produce the whole batch.

Ideally, you would also know where the key components are made, and you would make sure that that factory is also well run. But realistically, in China, the only way to ensure this is to find these sub-suppliers yourself.

c) The factory agreed to do a pilot run (or maybe simply a few prototypes) using bulk components. You should come just after they have done this job. This is often necessary and is the best time for technical products. Unfortunately, few factories agree to do this, even for a first order.

d) You are an expert in the manufacturing of your products. If you feel the factory needs your technical skills, you should come when the goods are starting to go through the process steps that you think are the most sensitive.

e) Your order quantity is not large, and you don’t think the first finished products are representative of the whole order’s average quality: come when 30% of the goods are completed.

f) Packing is a very complex and/or sensitive operation. You should come when they are starting to pack the goods and train/supervise them. Packing workers are often the lowest paid in the factory, and can be hard-headed.

2. What to do if the inspector finds problems?

Again, the answer is “it depends on what type of problems were found”.

a) Production (or a part of it) is made outside of the facility you audited. When we find this case, it often comes as a shock to our client — especially if they are an intermediary that sells the goods to a mega-retailer such as Walmart.

You should ask for an explanation. Your supplier should give you guarantees that they are following production in that other manufacturing site very carefully. You should keep a close eye on what happens. For large orders, the number of subcontractors could go up to 10 or 15!

b) The components are substandard. Make sure production doesn’t start! Many Chinese factories don’t have “OK / not OK” gates. They don’t have the equivalent of start/stop buttons. When they have free capacity, they will be tempted to go ahead.

You should ask them to send the bad component(s) back to the supplier and to get a replacement(s). Ask for photos as evidence, and check the new components again.

c) The factory is not following the process you showed them. They might persist even after you reminded them of your requirements, and argue, “you don’t know how production works here”.

In that case, insist on having them do a pilot run before taking risks with a batch that was purchased in part with YOUR deposit. If that doesn’t work, follow closely how production unfolds.

You could also help them to produce work instructions for the production line, where each operating station has a clear set of instructions including photographs or images that show key steps for that part of the process. For example, you can follow this template.

d) Many, or all, of the products have problems. First, make sure production stops until a solution is found. They should not keep making the same defects. They should find a way to correct their process before resuming work.

Second, give them clear criteria to guide their 100% sorting job. They will have to go through the goods they have already made, to decide whether they are acceptable.

All of the goods that are NOT acceptable must be clearly identified and ideally quarantined away from the production line.

3. Checking earlier is better

By now you certainly understand why checking earlier is better. Catching problems early gives you the time to study the problems, tell the factory what is not acceptable, look for countermeasures and test them, and adjust your schedule.

As you can guess, for large orders it often makes sense for the customer to send inspectors at several times during the production cycle. In certain cases, an inspector is stationed for several weeks in the factory.

If you wait until the whole production is completed and you find quality issues at that point, it might be too late. Sometimes re-working the defective goods takes weeks. And they might all need to be re-produced, which is very time-consuming and expensive… and is rarely done at the factory’s cost.

The sad truth is that, even though most production problems are the manufacturer’s fault, they rarely take responsibility. This is why enforceable contracts (see part 6 about leverage) can save your a**!

The general rule is, the earlier you find an issue the less expensive it is to rectify. It’s also known as the 1:10:100 ratio:

- Fixing problems in development is about 10 times faster and cheaper than in production.

- Fixing problems in production is also about 10 times faster and cheaper than after the products have been sold.

- Consequently: fixing problems in development is about 100 times faster and cheaper than after the products have been sold.

4. A few more benefits of early production inspections

Inspection during production is also an easy way to draw a few samples from production and to send them to a testing laboratory. If you only do this during a final inspection, you might have to wait for the lab’s result for a week before giving the green light to the supplier to ship.

The inspector will use the specifications you have written as a checklist, and if possible an approved sample for reference. That’s where the hard work you did after lesson 7 starts to bear its fruits.

The topic in part 10 will be final inspections, and why they are most importers’ preferred quality control tool.

>> Move on to the next post in this series. Read it here: Sourcing from China 101, Part 10: Always Verify Quality Before Shipment <<

Are you trying to find a manufacturer in China who is well-suited to your needs and can also deliver on their promises?

Sofeast has developed 10 verification steps to help importers find the right manufacturing partner in China. They’re shared in this FREE eBook: “How To Find A Manufacturer In China: 10 Verification Steps.”

It covers:

- Background checks

- Manufacturing capabilities

- Quality system auditing

- Engineering resources

- Pricing, negotiation, & contracts

- …and much, much more

Just hit the button below to get your copy and put yourself in a great position to get better results from Chinese manufacturers who supply your products: