This is the second part in the series about the management of QC inspectors in China. I am looking at two very important parts of the preparation.

This is the second part in the series about the management of QC inspectors in China. I am looking at two very important parts of the preparation.

Common shortcomings

Here are a few issues that I often see:

- A “golden sample” is approved, and it is the only standard to be followed. But a golden sample is not sufficient. It does not include critical information such as the severity of potential defects, how certain tests ought to be conducted, etc.

- The buyer does not specify what packing and packaging elements are required. “Packing must protect the goods adequately during transportation” is not a precise standard. Should there be inner cartons? Special protections? What type of cartons are to be used? Should pallets be used? Etc.

- The buyer leaves a lot of subjectivity in the inspection process (for example: “the veneer must look nice.”). They see it as an art more than a science. It means two inspectors will often find different things, and it makes the whole process very unreliable.

If we take a step back, these shortcomings impact production quality in the first place, since the supplier also needs to know all this. Which means… an inspection is even more necessary! Unfortunately, the inspection can’t take place in good conditions if the preparation was overlooked.

In the next paragraphs I will explain what information the supplier and the inspector need to know.

Defining a clear and detailed checklist

Without a list of checkpoints to follow, an inspector has to rely too much on his/her memory and tends to lack a proper structure to follow.

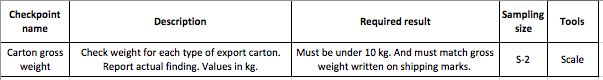

But a list is not sufficient. “Check carton weight” is not detailed enough. Instead, a checkpoint should look like the example below:

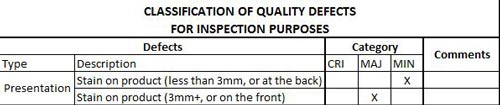

Similarly, making a list of potential defects without assigning a severity (critical / major / minor) to each of them leaves too much subjectivity to inspectors. At a minimum, you should prepare a list on this format:

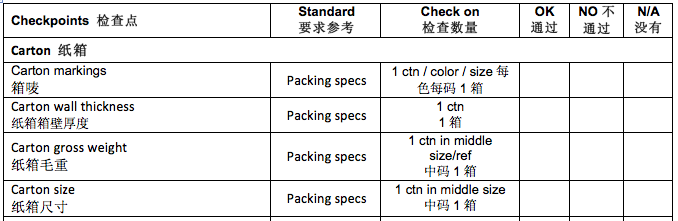

The best practice is to integrate the checklist into the reporting form. This way, the inspector has to fill out his form and follow the checklist at the same time. Here is a very simple example:

Making sure the right equipment is available

Once a checklist is in place, you need to define:

- What equipment needs to be brought by the inspectors (usually small tools), and

- What equipment needs to be in the factory (usually bulky devices, or very specialized equipment).

Nothing is more frustrating than an inspector who went to the factory but can’t check a very important criterion because he lacks the proper equipment. You need to ensure all the equipment will be available.

You also cannot take decisions based on unreliable data. The gauges, callipers, and other checking/testing equipment need to be calibrated at appropriate intervals. Either someone in your office does it (based on a master standard that is very precise and accurate) or you work with a testing lab — it doesn’t matter much.

This creates an obvious problem: how to be sure about the factory’s equipment? You might have to brief your inspectors to do some very simple tests first. For example, when a digital scale from the factory needs to be used, does it indicate “0 gram” when it starts? And does it indicate 25g for a pen that weight just this much?

—

I hope this advice is useful. What do you think?