I am halfway through this book and I thought many readers would enjoy it: Product Realization: Going from One to a Million by Anna C. Thornton.

Here is the book’s presentation by its publisher:

Product Realization: Going from One to a Million delivers a comprehensive treatment of the entire product launch process from beginning to end. Drawing upon the author’s extensive first-hand experience with dozens of successful product launches, the book explores the process of bringing a design from prototype to product. It illustrates the complicated and interdisciplinary process with vignettes and examples, provides checklists and templates to help teams, and points out common challenges teams will face.

The author has worked with a number of large companies as well as funded hardware startups. She is now a professor of Mechanical Engineering at Boston University.

What is in this book?

The book covers pretty much everything from writing product specifications to delivering the product to customers. It does not really cover the product engineering design work (there are already many books about that topic), but it covers in great detail the steps between “product design is done” and “mass production is going smoothly”.

That’s what we call the NPI process, and what is called the EVT-DVT-PVT steps in consumer electronics (I discussed them in this video). “Product realization” is a term used in ISO 9001, but not very often used by practitioners.

It was written as a textbook (hence the higher price). It covers many topics and at the same time is relatively exhaustive. The majority of the content is about the technical side of the work to bring a new product to market. But there are a few chapters about the supply chain side, too.

The author obviously worked a lot on electro-mechanical products that aimed at relatively large volumes (mostly consumer electronics, I’d guess).

If I were asked how to make the next edition more useful, here is what I’d suggest:

- Include advice for smaller companies all throughout the chapters. This book will help a project manager with a development & NPI budget under 200,000 USD, there is no question. But he/she will have to make decisions and skip certain steps.

- Move the chapters about setting up the supply chain earlier in the book. If the right type of contract manufacturer is not chosen, and if the right type of contract is not signed, a good chunk of the advice in this book cannot be followed.

What I appreciated most in this book

In addition to all the spot-on and well-explained advice, this book gives advice that is tightly aligned with what we’ve been preaching.

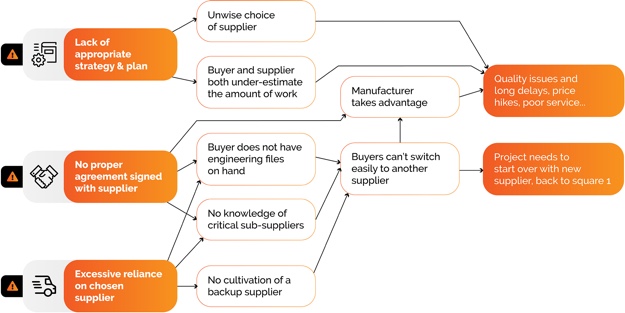

She warns the reader about all the fundamental mistakes we outlined in our guide to new product manufacturing:

When people contact us and discuss their new product idea, they often have a preliminary (immature) design and they think they are getting very close to mass production… This textbook will be one more way for us to explain that they still have 6-10 months of work.

The author compares the new product development process to a marathon, which includes:

- The first mile: exploring an idea, confirming it, having a preliminary product design, etc.

- The last mile: selling the products to customers, getting paid, etc.

- “The middle 24.2 miles” which are much longer and more painful than most companies expect.

And she gives long lists of typical mistakes to watch out for.

Successful product realization requires coordinating a large number of activities to define, test, and deploy all of the systems to mass produce at high rates. It is not a matter of merely flipping a switch at the factory. Instead, each aspect of the production system has to be tested and debugged. No company can go from first test shot to full production rates instantaneously, because no company can get everything right the first time. During piloting, teams will scramble to redesign parts, re‐cut tools, work with suppliers to improve quality, change assembly sequences, and undertake a myriad of other efforts to hit their launch goals.

Tell me what you think

If you end up reading this book, let me know your thoughts. Does it influence you to change the way you’re developing and manufacturing new products? I’ll read all your comments.

Are you designing, or developing a new product that will be manufactured in China?

Sofeast has created An Importer’s Guide to New Product Manufacturing in China for entrepreneurs, hardware startups, and SMEs which gives you advance warning about the 3 most common pitfalls that can catch you out, and the best practices that the ‘large companies’ follow that YOU can adopt for a successful project.

It includes:

- The 3 deadly mistakes that will hurt your ability to manufacture a new product in China effectively

- Assessing if you’re China-ready

- How to define an informed strategy and a realistic plan

- How to structure your supply chain on a solid foundation

- How to set the right expectations from the start

- How to get the design and engineering right

Just hit the button below to get your copy (please note, this will direct you to my company Sofeast.com):