This framework will help any entrepreneur who has successfully crowdfunded a product to understand how to start manufacturing.

Now, what to do? What are the steps to have the first batch of products made in China?

We’ve got Kickstarter funding, now, how to start manufacturing our products?

You have already done a lot of work and you have a look-alike and (hopefully) work-alike prototype and have also raised money on Kickstarter or another crowdfunding site. Congratulations!

That’s a nice form of market validation, and it helps meet your financial needs.

If your product is very new and relatively complex, having the first prototype is only a small part of the work on the road to getting a first mass-produced batch on the market. As I wrote before, it often takes much longer than expected.

Let’s explore the 10 manufacturing steps entrepreneurs and hardware startups should follow to get your crowdfunded product from its Kickstarter page into the hands of your excited backers.

Keep reading to see step each in order:

1. Review your design based on DFM (Design for Manufacturing) principles

This is typically a review of your design by someone who knows how Chinese manufacturers tend to make this type of product.

(Ideally, that would have been done before any prototype was made and used for commercial purposes, but later is better than never.)

This review might point to the need for changing some of the materials or fabrication/assembly methods.

Some of the most frequent benefits are making processing easy, simplifying the product in order to avoid potential points of failure, ensuring components can be sourced locally if possible… In the end, it often means lower costs AND better quality & reliability AND fewer delays / shorter lead times.

We have suggested this step to some companies that went straight into mass production and had to make the painful decision of changing a material at a time when it proved quite expensive to them. Don’t be in that situation.

Note: design can be reviewed for many objectives. See 12 examples of DFX approaches.

2. Identifying & vetting some suppliers (components, assembler)

Your product got a good reception in the marketplace. You are planning to manufacture at least 2 or 3 batches of the current version, right? In that case, reduce your risks and work with the right people from the start.

A risk here is to work with cheap suppliers — for example, you buy a metal flask and you buy from a small factory in the Yongkang area in Zhejiang. Things look easy at the start, but you will probably get into numerous issues with them.

Another very serious mistake we have seen is engineers who procured components on TaoBao (China’s local Amazon) for making prototypes, and who kept using the same parts for mass production. A 20% defect rate is going to hurt your project significantly… Don’t do that.

Take the time to vet your suppliers. And get a backup when it comes to the 1-2 most critical elements in your supply chain. We recorded a webinar on this topic.

3. Define clear expectations

There are many angles here:

- Can potential suppliers spread your information, or use your files to copy your product? Use a non-disclosure, non-use, non-circumvention agreement that is applicable in China.

- Who owns the intellectual property, who can manufacture the product, who can sell it? Get the supplier to sign a development agreement that is applicable in China.

- How is the supplier supposed to behave in some frequent cases (e.g. what penalty for delays, what consequence for quality issues…)? Get the supplier to sign a manufacturing agreement that is applicable in China. I’d suggest you read this article, too.

- What will be tested/checked, and what will constitute good quality? Define a product specifications sheet and design files. (Think of it as the QC checklist that will be used during inspections, to confirm you can accept a batch of products.)

I could go on and on here, but these are the pieces of the puzzle that you really need to have in place from the start.

A good deal of this is China-centric legal agreements, and I’d suggest you contact capable lawyers such as Harris Bricken.

4. Prepare more refined prototypes

Don’t go into mass production if you don’t have a final prototype in exact materials, exact colors, exact functions, and so on. And it has to include packaging. It should be made of components coming from the suppliers that will be used for production.

Which means that, at the same time, you’ll need to make sure the suppliers are qualified in a structured manner (I’d say 98% of manufacturers are very weak on that point in China), and build the BoM (Bill of Materials).

It is important that you have direct visibility of the BoM — at least when it comes to the most critical components. The assembly manufacturer will probably resist that, which is why this requirement should be discussed at the very beginning of discussions.

All this is typically prepared by the manufacturer that will do mass production (usually assembly and sometimes some of the fabrication, too), however, in case of an immature design, it might have to be prepared by an outside engineering & supply chain management agency before it can be given to a manufacturer.

5. Certification(s)

Have you researched what certifications your new product will be subject to? For example, your electronic product might need to be FCC and/or UL certified for selling on the USA market.

This has to be done on a final prototype, in the same components and made the same way as mass production. It is not cheap and not fast.

Ideally, compliance needs to be taken into account at the design stage (this is part of DFM – see section 1 above). We wrote some advice on this before.

6. Reliability testing

Some quality issues might only be caught by subjecting some products to real usage simulations (including extreme temperatures, vibrations, etc.).

I wrote before about reliability testing for electronic products. But it can also be done on many other types of products that have to withstand certain environmental conditions and/or usage patterns.

For example, ‘a user must be able to sit in a chair and recline the back support 2,000 times’ is an objective that can be tested. In some cases it is a mandatory regulation, and often it is simply a way to confirm that consumers will have a good experience with the product.

6. Get tooling prepared and signed off

If your product has a custom-designed casing, a mold (e.g. for the plastic injection or the aluminum die casting) will have to be prepared. Again, it is not cheap and not fast.

In many cases, some important non-recurring engineering is needed to reduce risks and cut total costs. For example, fixtures to make assembly easier, go/no-go gages for stopping parts out of a critical spec, an automated packaging line, and so on and so forth. The higher the projected volume, the more time and money you’ll want to spend here.

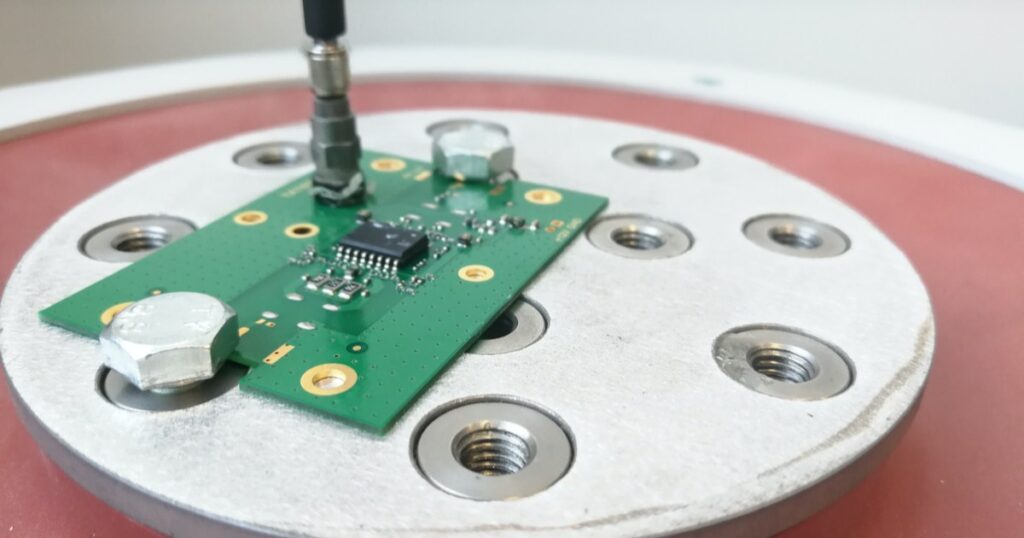

7. Get testing stations prepared and signed off

This is similar to point 6. You might need custom-developed testing stations to catch defective units, and this is especially common for electronic products.

Don’t go to the next step until this is ready, at least on a rudimentary level.

8. Pilot run before production launch

Make sure the pilot run is not skipped – most Chinese manufacturers hate to do a setup and provide a lot of engineering & management attention for a very small quantity, and yet it is a very important step for new products.

ALWAYS REMEMBER, CHINESE MANUFACTURERS TEND TO PUSH YOU TO SKIP IMPORTANT STEPS BECAUSE THEY WANT TO REDUCE THEIR WORKLOAD AND COLLECT PAYMENT EARLIER… AND BECAUSE, IN GENERAL, THEY ARE TAKING RISKS WITH THE CUSTOMER’S MONEY!

In >95% of cases, major issues will be detected and will need to be addressed: inconsistent component quality, a process that is not capable of sticking to spec, a checking gage that doesn’t detect certain issues…

If there are serious problems, ask for a second pilot run, to confirm they have been addressed effectively.

Three pieces of advice:

- The presence of your team on-site during this step will help greatly in keeping the pressure on the manufacturer and also in understanding the whole process.

- If there are uncertainties on a custom-developed component, it should also be subject to a pilot run.

- If you are on-site, make sure to note the yield (% of good pieces), as the supplier might invoke a very low yield to bump pricing up.

9. Monitor the first production batch closely

If you can’t be on-site during production, send a specialized agency to conduct inspections. If you followed the advice of section 3, you will reap the benefits of that service, since you have a checklist ready and the supplier accepted the fact that external inspectors will come.

I wrote about quality inspections here. It will also allow you to be aware of the real production status.

10. Learn the lessons of the first production batch

You have a limited budget and tight deadlines. You may have skipped some of the steps I listed above. And you will have run into issues — I’d guess no launch of a totally new product goes smoothly.

Ask yourselves:

- What issues do you want to avoid in the future? And what needs to be done?

- Where do you feel you got lucky, but you need to have extra processes in place to cut your risks?

This is the real life of real projects. There are always adjustments and improvements. Some suppliers need to be changed, the design of version 2 needs to avoid certain risks, etc.

*****

Did your project follow these steps? Where did you take a shortcut, and where do you feel my list falls short? Any other tips about how to start manufacturing to share with our community? Let me know by leaving a comment, please.

Are you wondering how to find a manufacturer in China who is well-suited to your needs and can also deliver on their promises?

Sofeast has developed 10 verification steps to help you find the right manufacturer. They’re shared in this FREE eBook: “How To Find A Manufacturer In China: 10 Verification Steps.”

It covers:

- Background checks

- Manufacturing capabilities

- Quality system auditing

- Engineering resources

- Pricing, negotiation, & contracts

- …and much, much more

Just hit the button below to get your copy:

One Response

Starting to manufacture your product can be exciting. But you must remember to make sure your IP and design are well protected, especially in ASEAN countries. Don’t let counterfeit goods steal your sales and ruin your band’s reputation. https://www.intouch-quality.com/blog/protecting-your-ip-and-design-rights-in-asean-countries?utm_campaign=YouTube%20Outreach&utm_source=blogcatalog&utm_medium=social&utm_term=kickstarter