New product introduction is a complex process to master, and SMEs and hardware startups we often work with find it very challenging and seek our help to devise and manage the different steps in order to get into mass production on time, on budget, and with products that are reliable, safe, and good quality.

We have written about the NPI process and the design and development of new products extensively… here we’ll look back at some key posts and a new video we created, so you can get an understanding of the tasks, risks, and who is involved in a successful NPI project and subsequent mass production.

The NPI Process is more lengthy and complex than you may think

It’s essential to follow a comprehensive NPI process in order to reduce risks to your product’s quality, reliability, safety, budget, and delivery time.

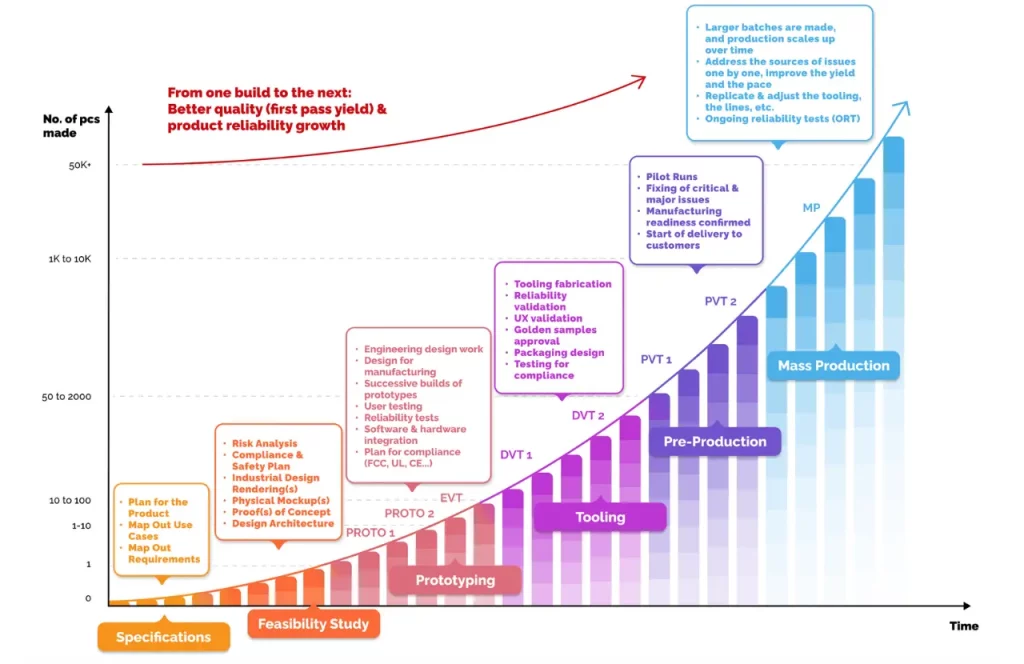

Here is a simplified representation of the NPI process. You can see by the numerous phases and the increasing number of pieces (prototypes used in product testing and validation) made over time before production starts that skipping NPI phases to ‘save time’ is false economy and actually results in poorer quality and reliability once products are in consumers’ hands:

(Click on the image to enlarge it)

I’ve addressed some common questions about the NPI process in earlier posts:

If we have a good prototype, can’t we just start mass production?

A typical risk of the new product introduction process that’s relevant here, especially when working with Chinese manufacturers, is that going from 1 prototype to mass production directly is dangerous. Your manufacturer’s motivation in many cases is to get your product mass-produced and shipped as soon as possible because this is when you send them payments.

However, this financial incentivization can be risky… just because there is an excellent prototype in hand, can they guarantee that the thousands coming off the line during production will be at the same standard, with very few exceptions?

In fact, there are around seven prototyping and verification stages between early prototypes and mass production during the NPI process, and skipping them increases your risks.

How long does it really take to get to a ‘final prototype?’

It’s also necessary to get a handle on when you might expect to get to the final prototype of a new hardware product. This is because importers often underestimate the time and effort it takes to design the products, as well as to go through the various rounds of prototyping and creating numerous samples before you arrive at a final prototype that allows the transition into mass production.

When can we transition from product development work into production?

In how & when to transition from a product development team to a manufacturer I explored why a product development team is often better suited to certain activities than relying solely on a manufacturer to do everything, especially the initial product design and development through to making final prototypes just before the project is finally handed over to a manufacturer. The manufacturer, on the other hand, may be more involved in the sourcing and product quality and reliability side of things if they have the necessary competences. Of course, the buyer is also involved throughout in differing degrees, too.

How involved should YOU be in the NPI process, though?

After reading the earlier posts, the reasons for following a thorough NPI process should be quite compelling, and what such a process realistically involves should be clear, if somewhat daunting for those who are new to launching new products.

The next question we sometimes get, though, is: “How involved do I need to be in this process?” Understandably, some importers who’re less experienced seek to work with partners who have ‘been there and done it’ and have a systematic and proven NPI process.

This depends a great deal on two things:

- How much business you’re giving the manufacturer and your subsequent ability to make demands of them.

- Your manufacturer’s abilities and level of experience in bringing new products into production at a relatively high level of quality & reliability as well as productivity.

Here’s a video I made outlining your involvement in managing the NPI process with a focus on the above two criteria on our YouTube channel.

In summary, here’s your rough involvement.

1. You provide a lot of business to a very capable and experienced manufacturer.

This is the ideal situation. The manufacturer has experience in bringing similar products to market and has successfully implemented a good NPI process in the past. Not only that, they have the staff to handle it and are motivated to get it done well and soon because you’re a good customer. In this case, you can afford to be more hands-off and let the manufacturer handle the NPI work and transfer to mass production, just be sure to check in with them regularly and review the deliverables to confirm that you’re happy with the results.

The outcome should be that the NPI process is streamlined and you can rely on the quality, reliability, speed, and estimated lead times.

2. The manufacturer is capable and experienced, but they don’t consider you to be a major customer.

The manufacturer may have a lot of in-house resources to handle the NPI process well, such as engineers, a sourcing team, and so on, but they may not release these resources for your order because it’s not significant to them.

They may follow NPI best practices, but expect to be at the back of the queue compared to other customers, which could negatively affect your lead times. You may be assigned to their ‘B-team’ staff members or, at least, end up being a minor priority for their first-class project managers, for example.

In this case, doing the NPI work yourself (by outsourcing to experts if needed) may get your project into mass production sooner than waiting for the manufacturer to free up the resources and ‘get to’ your order, although their quality, etc, should be reliable.

3. The manufacturer is less sophisticated and your order is quite small.

Probably the worst-case scenario, because you, the buyer, need to do all of the NPI work and the manufacturer may not consider you a priority.

You can’t rely on this manufacturer to do the important NPI work as they probably just don’t have the in-house abilities and staff to handle it. Either they simply won’t have the resources to offer, such as designers, engineers, etc, or the risks of mistakes are too high.

With this manufacturer, you will need to go to them with a very mature product design that is truly ready to transfer to mass production and only use them for the manufacturing part alone. Otherwise, they may not be very motivated to work on the order.

Therefore, you should consider outsourcing the NPI work to a third-party design house and/or product development team who will plan, develop processes, create the testing plan, etc, and have everything ready for mass production and may even need to send engineers to the factory to help guide the manufacturer and keep them on track. Note that very few design houses can truly do all this, and that’s a big part of the problem here.

If you decide to leave NPI to this manufacturer it could be a shorter process, but you can expect them to skip NPI steps (not good, see above) and rush into production because that’s where they’re most comfortable and they get paid sooner, too.

4. You’re a major customer, but the manufacturer is not very sophisticated.

You are still dealing with a relatively unsophisticated manufacturer, but now you have the sway to drive them to hire the staff required to undertake the NPI process effectively. That being said, in this case, you will still need to manage the project and be hands-on, giving them templates and defining your expectations and deliverables for the project.

It could be a lengthy process if you follow this approach because it will take time for the manufacturer to find and recruit the right engineers, etc, and you will still need to work hard to manage the project from the outside and watch the manufacturer closely to assure that they are on target to meet your expectations.

*****

Which type of manufacturer have you been working with, what went well, and what could have been better?