Many importers are looking to hire this type of profile in China:

- Can do ‘project management’ and follow up on developments and productions

- Can do quality inspections

Can the same person do both? Yes, absolutely.

Do some companies have the same people do both? Yes, and sometimes with success.

Is it easy to set this up? Not without a strong company framework around the employee and close management.

The first obstacle is the differences in typical profiles:

- QC inspectors can generally read/write English but are not good at interpersonal communication.

- QC inspectors are typically detail-oriented but might not be good at understanding the ‘big picture’ idea (how to manage the supplier etc.).

- Project managers need great communication skills, including spoken English, and need to be holistic thinkers.

- Project managers are seldom trained in the QC inspection procedure, and it is easy for factories to play games.

The second obstacle is the risk of mixing the two roles:

- Sending the same inspector to the factory is not advisable. They might become friends and become too lax (‘you fed me well and picked me up many times, so I’ll under-report this issue’) or they might hate each other and clash.

- Having the same person handle commercial and quality issues sends a clear signal to suppliers: these issues are linked. The natural tendency of Chinese suppliers is to mix everything up and you should not encourage it. Otherwise, be ready to hear “quality is not great but the price was low”.

- There are no checks and balances.

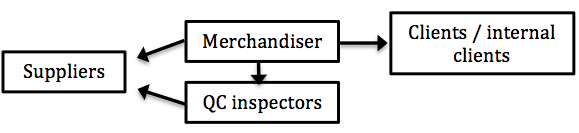

So, how should a team of project managers and QC inspectors be structured? I suggested this organization in a past article about purchasing offices:

- A team of 1-3 merchandisers (the word means different things in different industries, but generally they do what some call project management) follow up on some orders.

- A few inspectors work ONLY on that team’s orders.

- Merchandisers spend 1-2 days a week in factories, together with inspectors.

- QC inspectors are in factories nearly all the time and might come to the office on Monday morning (for example).

Does it make sense?