What’s the best way to get started with quality management?

It makes a lot of sense to work to improve your product quality coming from Chinese suppliers and you don’t need to be a large corporation to do this, but this kind of quality management is best when it follows a process. So in this episode of the podcast, we discuss what the quality management process is, and its 3 main parts: quality planning, quality control, and quality improvement.

By understanding how to put measures in place which, over time, which will improve product quality, you’ll be provided with higher-quality, safer, and more compliant products from suppliers.

The best way to get started is to document your requirements.

Once your suppliers know what you can and cannot accept, it’s time to start checking product quality.

Later on, you can then look into improvement activities based on the inspection results (this is a more advanced step).

Here’s what we’ll be discussing…

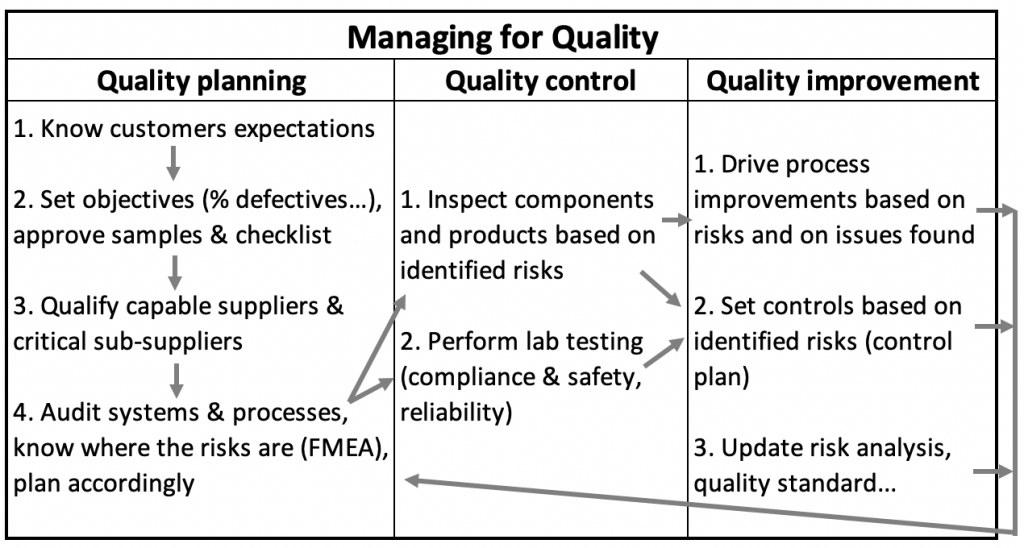

Both the basic best practices that any buyer who’s new to quality management should pay attention to and more detailed and advanced steps like setting up preventive maintenance or a process control plan are discussed in this episode. Renaud shares his experience to outline the entire QM system which is illustrated as follows:

Listen to the episode right here 👇👇👇

🎧 The Basics of Quality Management for Buyers 🎧

Here’s a summary of what’s in the episode:

✅ A quick summary of the quality management process and the Juran trilogy

✅ Benefits you can expect to gain when actively managing quality as opposed to the drawbacks buyers who don’t do so face. Ultimately, can you trust Chinese or Asian suppliers to provide top quality products 100% of the time? If your answer is no, then implementing some kind of system to at least catch quality issues before products are shipped is a must.

✅ QM best practices for buyers who are new to this.

✅ Since driving positive change is an integral part of the QM process, how feasible is this for small buyers like FBA sellers?

✅ A detailed look at every step in the system and how they all link to each other:

- Document your and your customers’ expectations

- Set objectives

- Qualify supplier & material/component suppliers

- Audit systems and processes

- Perform product quality inspections

- Perform laboratory tests where necessary

- Start pushing improvements based on risks and quality problems found

- Put controls in place on risks

- Update your quality standard and risk analysis as new issues are found

- Repeat system and process auditing and subsequent steps

Keep reading about this topic…

- Explore this topic further: How Quality Planning Drives QC and Process Improvement

*****

Have you already set up a quality management system like the one outlined here? Do you have any points to add?

Please share your thoughts in the comments.

Subscribe to the ‘China Manufacturing Decoded’ podcast 👍

There are more episodes to come, so remember to subscribe! You can do so in your favorite podcast apps here:

- Apple Podcasts

- Spotify

- Stitcher

- Google Podcasts

- TuneIn

- Deezer

- iHeartRADIO

- The podcast’s website at China Manufacturing Decoded