When a new product is developed, two sets of documents are very important: On the technical side the design deliverables (component drawings, PCB schematic…) and on the supply chain side the Bill of Materials (BOM). Let’s look at the BOM and its importance here:

What is the BOM?

In essence, your bill of materials is the list of components/parts, materials, and accessories, that make up the entire product (including its packaging). It will help keep the new product manufacturing project on track at every stage and will evolve as your new product development progresses.

The contents of a bill of materials

A BOM typically includes the following for every component of a product or its packaging:

- Part number, description, unit, criticality

- Unit price, tooling price, sample price

- Payment terms, delivery terms, lead time, MOQ

- Supplier contact information

- Supplier approval status

- Specification and/or drawing status

- Quality standard status (approved sample, checklist…)

- Follow up actions

What does a BOM look like?

A BOM may start out as a spreadsheet, however later on manufacturers often input them into their ERP system. (The information on the parts is some of the most basic and important ones, and any mistakes at this point can have expensive consequences.)

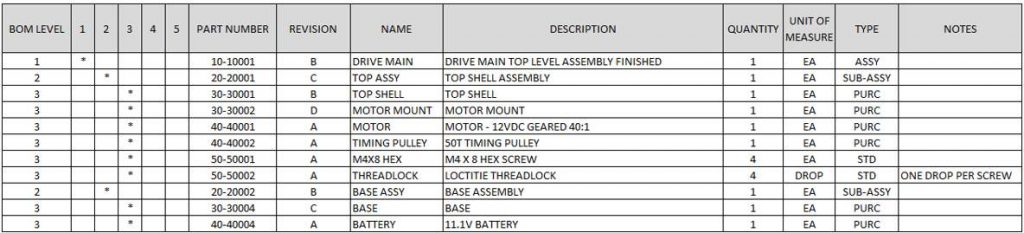

A good example of a Bill Of Materials can be seen here, I reproduce the image below:

(This is only a few of the columns — there is usually much more information in this document.)

I’ve also created this quick BOM walk through video where I demonstrate and explain some of the key parts that you may typically see:

How does a BOM evolve over time, and when?

Each BOM starts its life as a rudimentary list of components, with their corresponding prices, MOQs, lead times, and suppliers. This is the “initial BOM”, or “concept BOM”. The idea is to have a rough idea of the total price & lead time and to grasp the complexity of the product.

Then it becomes more complete, with some deliverables of the design & development process. The “design BOM” and the “development BOM” list a lot of information that was gathered and confirmed as the detailed design work, and the prototypes, are brought to life. Once a full work-alike and looks-alike prototype is approved, the BOM should be able to reliably tell the total price of the components.

Then, the process engineers prepare for mass production, and it becomes the “initial manufacturing BOM” and “manufacturing BOM”. It keeps evolving, as Engineering Change Requests come in and as suppliers that fail to deliver a certain level of performance get replaced.

Confidentiality

The Bill of Materials is a very confidential document!

Most Chinese manufacturers do NOT want their customers to see who they buy components from, how much margin they make, etc. (I wrote about this before in Why You MUST Know the BOM (Bill Of Materials) of ‘Made in China’ Goods)

Virtually no company wants its competitors to know who is involved in making their product, for obvious reasons. (There has been a clear trend toward transparency in the supply chain, but it is still only the case with a small minority of importers.)

How to get the BOM from my supplier?

The type of supplier you work with will influence how likely you are to be given access to the BOM. If you want to get it, you’re better off working with a contract manufacturer.

It’s highly unlikely that an ODM will provide it and you’re best avoiding an OEM, too, as these types of supplier typically won’t release that information.

Better understand how to make the choice between suppliers in this post: OEM, ODM, Contract Manufacturers: Choose your China Supplier Wisely

Conclusion

If you do not know what is in your key products’ BOMs, this is an area of concern as you will not have as much control over your supply chain as you require, leading to a greater risk of pricing, quality, or lead time issues moving forward.

If you are an importer, do you have access to the BOM? Do you find it useful? Let me know by leaving a comment, please.

Ultimate Guide To Sourcing From China And Developing Your Suppliers [eBook]

This FREE eBook starts from the beginning, discussing whether you need to hire a sourcing agent, and follows the sourcing process right through to developing a trusted supplier’s quality and productivity.

There are 15 chapters over 80+ pages to explore, providing exhaustive guidance on the entire sourcing and supplier development process from start to finish, including:

- Identifying suppliers,

- Negotiations,

- Quality inspections,

- Developing Chinese suppliers,

- Improving factory quality and productivity,

- and much more…