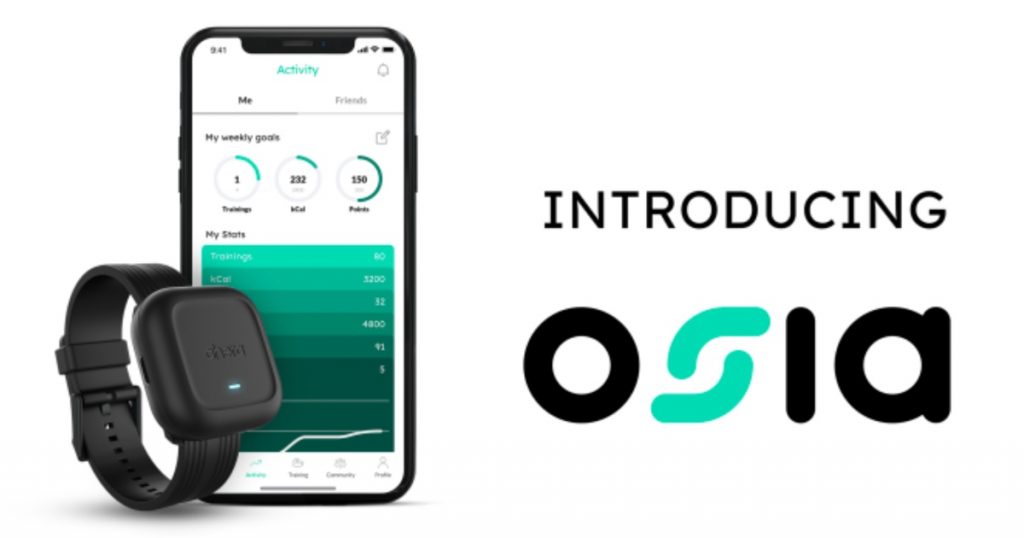

We’ve been fortunate to help Ahera develop their OSIA IoT smart band from concept to prototype and to get them prepared to take the next steps (tooling, certification, preparation, production).

It is actually a great case study for entrepreneurs planning to develop their own product and manufacture it in China, so I thought it would make for an interesting article.

Ahera is in the middle of an Indiegogo campaign these days. I went to interview their founder, Rudy Bottin, about what it took to get to this point, and what the next steps are. Here it is, in his own words:

What does the OSIA wearable do?

- It is worn during gym workouts, or affixed onto external moving elements (Watch this short video to see how it works)

- It sends activity logs onto the mobile app via Bluetooth in real-time, so you can plan, track, share and analyze every workout session

- You can set yourself ambitious goals, and plan & share your activity and progress.

Let’s look at a few key takeaways from this product development.

1. Conducting design reviews early on, and pivoting when necessary

The initial concept was a set of connected dumbbells that would send activity data to the user’s app, with a community to cheer and provide encouragement.

When a Design For Distribution review was done, they realized shipping the dumbbells to different parts of the world would be quite expensive.

They kept the key ideas (‘activity tracker’, ‘mobile app’, and ‘community’), but pivoted to a 40-gram wearable that can be affixed onto different types of gym equipment, making it more adaptable. This was an improvement in all aspects of the value to users!

2. Spending time talking to members of the target market

The team talked to a large number of gym enthusiasts. They showed about 50 different versions of the design, some of which were in 3D printed form, to collect feedback. This was very valuable work.

Many projects skip the market research stage, but we always advise “getting out of the building and talking to potential users” for two reasons:

- To validate that there is actually a market that will pay (and maybe also change their habits) for this product

- To get feedback and, sometimes, great ideas

We found that, when designers who see themselves as part of the target market (as is the case here) are involved in a new hardware product development, they tend to do a great job in this stage.

3. Focusing on having the best motion sensor

Our R&D team has done a lot of work on the STM 6-axis motion sensor (hardware, firmware, Bluetooth communication) since this is at the heart of the product. It has to work accurately.

Other mechanical elements support an aesthetic design but don’t try to be ‘bleeding edge’. (Over-complicating version 1 is another common trap for startups.)

This is how we got the waistband, the casing, and the packaging right with just 1 prototype iteration (!).

4. Confirming manufacturability before making the prototype

Many projects are successful on Kickstarter or Indiegogo but then fail miserably because they need a deep redesign before they can be mass-produced.

This project was planned from the start to avoid these issues. Here is what we did:

- We qualified suppliers that are capable of making large batches with acceptable quality (not just a few parts for a prototype);

- The tooling cost & timelines are already known since the mechanical designers have manufacturing experience and validated their drawings with component factories.

5. Using crowdfunding judiciously

SportTech IoT wearables have historically been a good fit for crowdfunding.

The Ahera team was careful not to dive into a campaign too early. Only when we confirmed the main assumptions and risks had all been addressed, did Rudy and his partners decide to go ahead with Indiegogo.