How many of your suppliers claim to be ISO 9001 certified? Is it true? And, to start with, what does it mean? I want to shed some light on this topic. The purpose of the ISO 9001 standard is to "help businesses and organizations to be … [Read more...]

Tired of Your Chinese Factories’ High MOQs & Long Lead Times?

A few months back, I wrote about how some buyers can no longer put up with their suppliers' quality issues. And I often lament on the poor state of quality systems here. In this article I'd like to mention the other enormous source of … [Read more...]

The Sad State of Quality Systems in Most Chinese Factories

The sad truth in China is, 5% of the manufacturers are doing a good job consistently, and the rest have ups & downs that irritate and frighten Western customers. And, of those 5% that do a good job consistently, 0.5% do so because of … [Read more...]

Do Good Manufacturing Practices (GMP) Audits Drive Improvement?

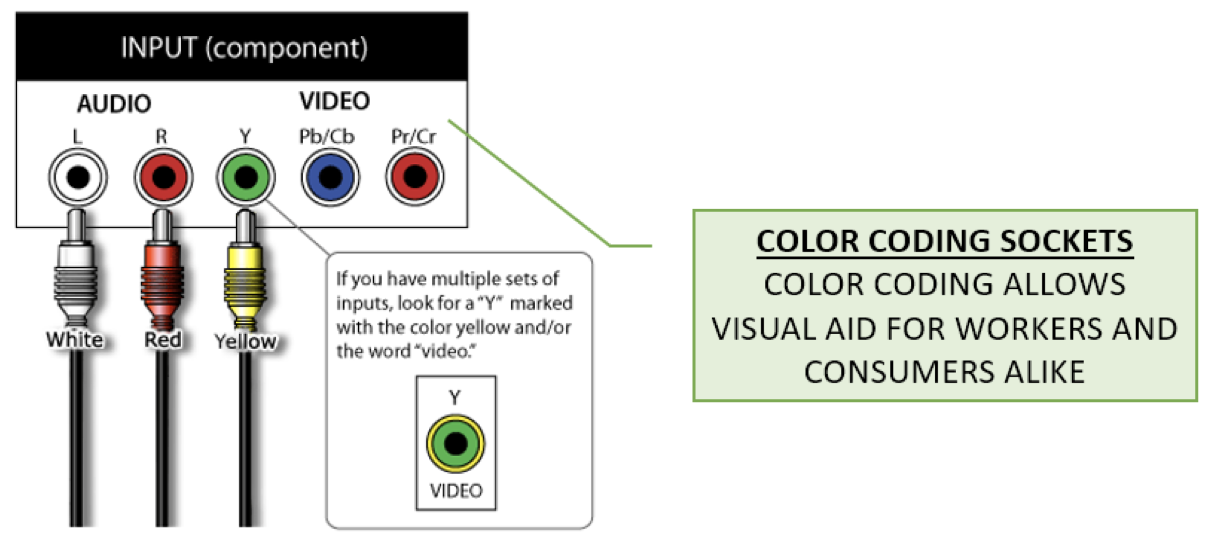

In any industry, there are generally-accepted 'good manufacturing practices' (or GMP). And customers often audit their suppliers' operations by using those GMPs as a checklist. First, what are those 'good manufacturing practices'? Think … [Read more...]

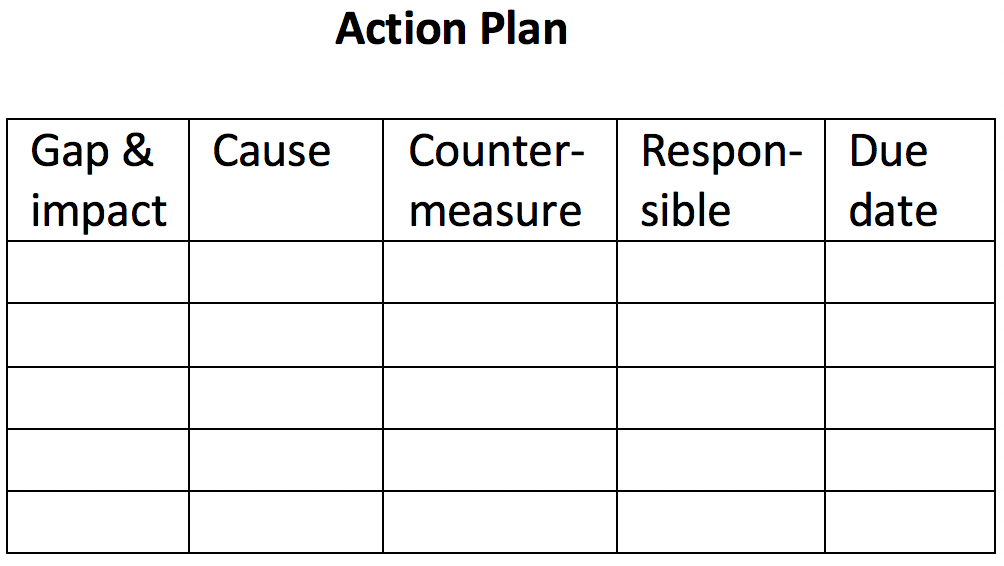

No Process Improvement Action Plan in Chinese Factories? Why?

In good factories, the leaders look at the future and wonder how to make their company stronger. They usually have an action plan that will support process improvement. That's how they will improve their quality, cut lead times, and contain … [Read more...]

Avoiding 9 Plastic Injection Molding Defects: Key Preventive Measures

Plastic injection molding is one of the most common production processes here in China. And most Chinese manufacturers are not very good at setting up and maintaining their presses and their molds and this leads to plastic injection molding … [Read more...]

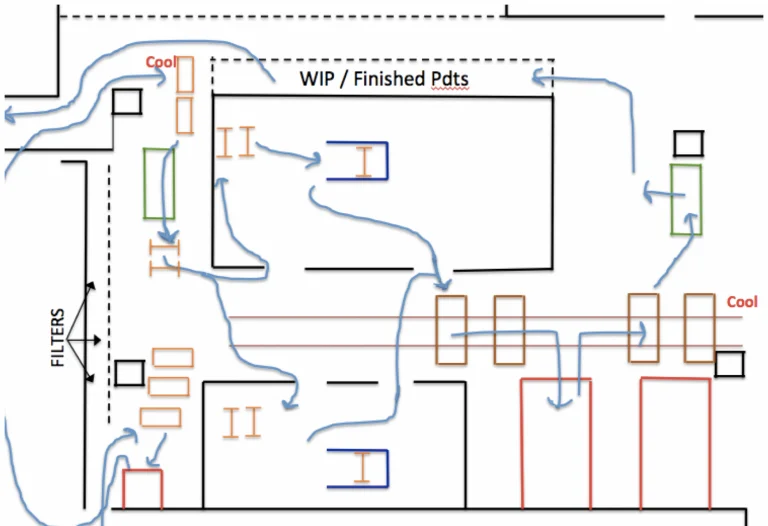

Sourcing from China 101, Part 15: How To Improve Factory Productivity

This is the last part in this 15-part series. Here we'll focus on how to improve factory productivity in China. Why is it important for buyers? Because, unless your suppliers make progress in this area in the next 5-10 years, many of … [Read more...]

Sourcing from China 101, Part 14: How To Improve A Factory’s Quality

I bet you are tired of hearing your Chinese suppliers say “this is made by hand, so avoiding defects is impossible”. So am I, because it’s so wrong. Some small factories have decreased their defect rate below 50 parts per million … [Read more...]

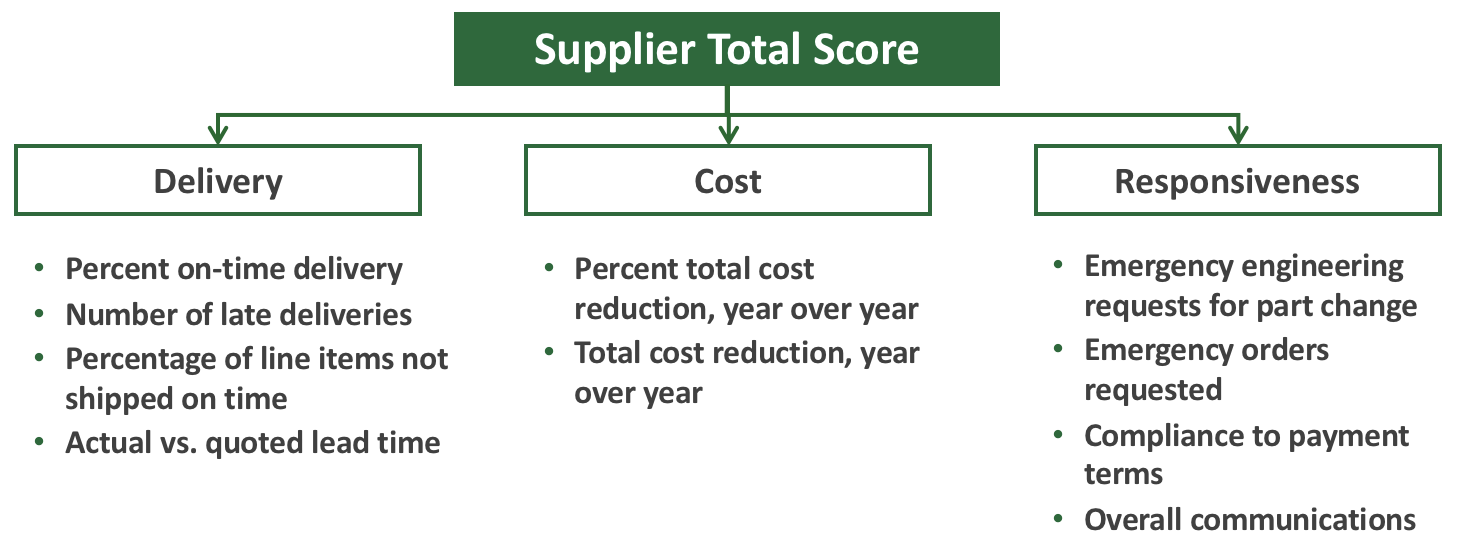

Sourcing from China 101, Part 13: Developing a Chinese Supplier

Many importers work in one or two product categories. They buy 80% of their volume from 1-4 manufacturers. And many of them make the same mistake: they don’t try developing a Chinese supplier who they are CURRENTLY working with. Instead, … [Read more...]

What Can Quality Professionals Do When Most Suppliers Are Off (CNY)?

Do you find yourself with some time on your hands, when your Chinese suppliers are enjoying their New Year holiday? Why not take advantage of it and do some work that will be important to your company's success? Here are 4 … [Read more...]

- « Previous Page

- 1

- …

- 3

- 4

- 5

- 6

- 7

- …

- 14

- Next Page »