We covered plastic materials in previous videos. Now we are covering their close cousin, the silicone rubber (often simply called "silicone"). It is easy to make on very common equipment (often the same used to mold thermoplastics), and … [Read more...]

Tips for Writing SOPs and WIs that Will Actually Be Useful

What is worse than not writing SOPs (standard operating procedures) or WIs (work instructions) at all? Creating inappropriate and bloated procedures. In this post, we'll look at the benefits of really good guidelines and explore the best … [Read more...]

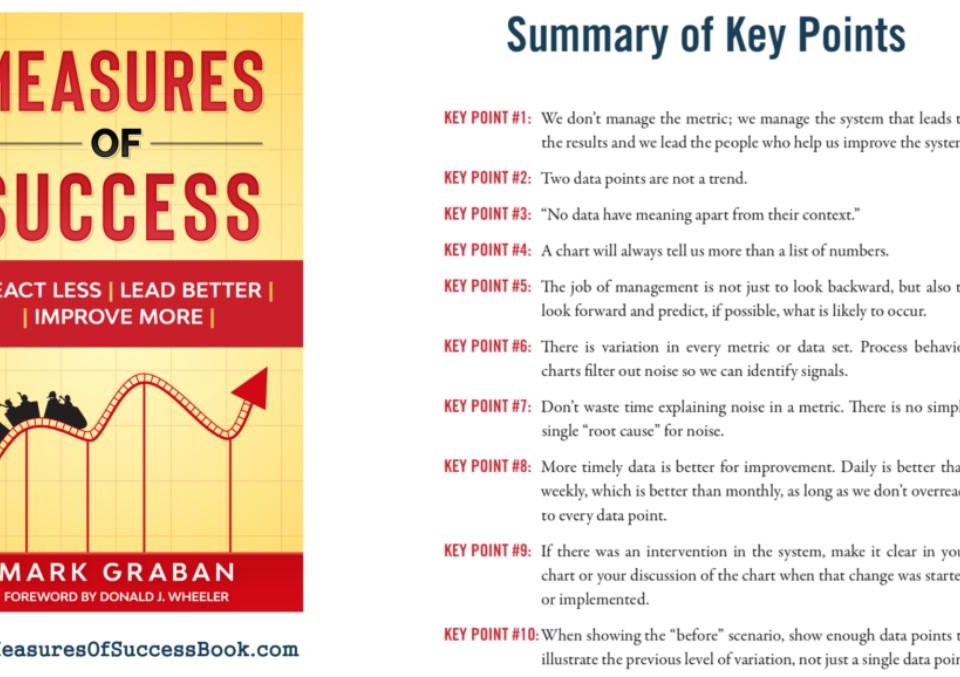

A Good Way To Analyze Data to Drive Process Improvements

I just read the book Measures of Success by Mark Graban, and I found it does a great job of covering the basics of how managers should work with data. His whole approach is largely based on concepts from Don Wheeler's books. If you are … [Read more...]

What Are Some Of The Most Promising IT Applications for Manufacturing Quality?

There has been a lot of talk about the "factory of the future", and the role of "quality 4.0" will play in that picture. Hundreds (maybe thousands) of IT applications, sometimes supported by IoT devices, have been developed. But what are … [Read more...]

Does ISO 9001 Actually Prevent Process Improvements?

As I wrote before, I believe that a good implementation of ISO 9001 does help a manufacturer quite a bit, while a bad one will only create issues. And the reason is simple. ISO 9001 allows an organization to set any system it wants, as … [Read more...]

Flexible Manufacturing in China: How To Set It Up

It is easier than ever for foreign buyers to have a manufacturer handle high-mix, low-volume orders, with short lead times. In other words, flexible manufacturing. … [Read more...]

Two Preventive Maintenance Examples: Go for More Structure

As I wrote before, preventive maintenance helps cut costs and improves quality. That's an extremely important element of good manufacturing and it doesn't get much coverage. Simply put, it extends the lifetime of the equipment, it … [Read more...]

11 Steps To Set Up a Process Control Plan

About 2 years ago, I wrote about the 3 process improvement tools we use most often. And today I'd like to do a deep dive into one of them -- the process control plan. … [Read more...]

All about the Metal Machining Process, Surface Finishes, and Tolerances [videos]

For all the talk about 3D printing (also called additive manufacturing), the vast majority of metal products are shaped into their final form by subtracting material using metal machining processes. Even when a component or product is … [Read more...]

Electronics Videos: Basics about PCB, PCBA, and the SMT Process For Importers

More and more products (both consumer goods and for industrial/commercial use) contain electronic parts - from dishwashers to remote controls and from small toys to functional MRI devices. If this is the case for some of the products you … [Read more...]

- « Previous Page

- 1

- 2

- 3

- 4

- 5

- …

- 14

- Next Page »

![Electronics: Basics about PCB, PCBA, and the SMT Process [Videos]](https://qualityinspection.org/wp-content/uploads/2019/09/ElectronicsBasicsaboutPCBPCBAandtheSMTProcessVideos-960x630.jpg)