We have worked with many companies that develop their own new product for manufacturing in China or Vietnam. They have spent months (or longer) on product design & development. But they completely overlooked why packaging is important, and merely plan to get to it at the last moment.

Oh, but wait… they still want custom printing. That often means a 3 weeks lead time, AFTER a packaging material & type has been confirmed, AFTER the printing supplier has been qualified (a step that is often skipped), and AFTER pricing has been confirmed.

What does that mean? Things often get approved in a rush, and the opportunity to use original packaging to drive product differentiation is lost.

When I search “yoga mat” on Amazon.com, it shows more than 1,000 results. For “laptop case”, you will get over 10,000 hits. And these numbers will only keep increasing. If you are in a similar category, you need to think hard about how to be different.

Inspiration for driving product differentiation

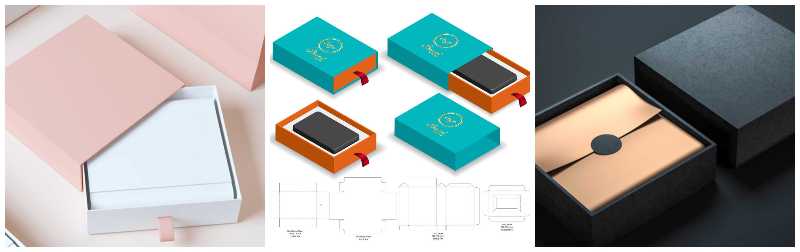

Since we are often asked what types of packaging are available, we prepared this nice guide:

Importer’s guide to 8 types of packaging

You may want a nice and high-end cardboard box below to convey a luxurious and/or “wow” feeling.

You may want to keep things simple, inexpensive, and functional. (Think ‘pizza box’ or ‘cereal box’.)

You may want to use a container that can be reused – it is a bit of a giveaway.

Or you may want to use eco-friendly materials.

We tried to cover all of these needs. Let us know if you think of something else and we will try to add it!

But enough about the unit (product) packing. Let’s also look at another very important function of packing materials.

You also need to specify the inner and export packing, for adequate protection

Imagine your first batch of products is delivered, after months of work. And you find out they got crushed and/or broken because of inadequate protection. You may be at a complete loss on this order, not to mention the disappointment of your customers who were counting on you.

One of the most basic rules for importers who purchase in low-cost Asia is as follows:

You are responsible for specifying what the manufacturer has to do and how it has to get done; you cannot count on a supplier’s experience, however confident they seem to be.

(In case they show you what they’d do, you can, of course, study it and approve it… but don’t forget to document it, so they know it’s not optional.)

Where to start?

You need to have an understanding of the typical trip your goods are likely to take. Here are a few examples:

- If you book a full container, it is safer than LCL (i.e. shared with other goods, which might be very heavy and crush your cartons).

- If cartons are placed on pallets and shipped by container to a distribution center, which then sends individual cartons to stores, the risk profile is completely different from drop shipping (one product at a time shipped all the way to the consumer).

- If inner cartons become the master shipper carton at one point in the fulfilment, they are also highly exposed to potential damages.

Common ways to protect your goods

I gave a list of examples of protective packing methods before in How to Protect your Shipment Effectively. It covers, among others:

- Classic cardboard boxes (quality, thickness, dryness, size, sealing)

- Carton boxes within carton boxes

- Crates and wooden structures with reinforcement

- Pallets

I would add that providing clear requirements for loading is very important:

- The typical Chinese manufacturer doesn’t pay much attention to putting the heaviest goods (if any) at the bottom.

- We have seen cases where the cartons didn’t all fit nicely, so the factory staff used a fork-lift truck to push them in (and crush some of them, naturally). Make sure you keep a safety margin. Don’t plan on using 3o or 31 cubic meters in a 20′ container…

- I’d add that unloading a container can take hours of expensive staff’s time if the cartons are stacked up without pallets. Think of the optimization of your total costs, not just the narrow transportation costs.

How to confirm the packing will provide the necessary protection?

By simulating the conditions it will be subjected to.

Common tests include:

- Free-fall carton drop test

- Carton compression test

- Carton vibration test

Let’s take the free-fall carton drop test, for example. The most commonly used standard is probably ISTA 1A, which calls for dropping the carton 10 times on the floor in a certain sequence.

If you manage at least tens of shipments a year, that standard should only be a starting point. You may be able to make the test more representative of your transportation & warehousing conditions, and that may allow you to both reduce cost (e.g. less material, lower volume) and improve protection at the same time.

In How to test the protection of your products during transport, Kevin Howard, a packaging consultant, stressed that following an established standard blindly may not be in your interest:

Many companies use standards such as ISTA (International Safe Transit Assoc), ASTM (American Society for Testing and Materials), JIS (Japanese Industrial Standards), and others. If one compares these standards, you’d find that no two are identical. This means it may be possible to pass one set of tests but not another, even though the products end up next to each other on the store shelf.

The problem with standards is that they know nothing about a specific product and its supply chain. Seeing that no two products and supply chains are identical, then why should different companies use the same test standard?

ISTA 1A is a test that verifies some minimum amount of protection, thus helping reduce business risk of catastrophic failures, but it does not purport itself to simulate actual hazards found within a specific supply chain. There have been no studies to indicate that a product would be dropped 10 times from a maximum height, so the drop test may well be excessive. At the same time, because the standard neglects certain orientations, it may cause a company to excessively package a product and yet still see damages because of a particularly weak orientation having not been tested.

Packaging is a very wide and deep topic. In this article, I wanted to give you a sense of why packaging is important — chiefly for differentiation and protection. Always remember, it is a part of your product and ensures its integrity. You can’t do without it. You can think of it in a purely defensive way (protection) or offensive (differentiation). But why not both?

Keep reading even more about packaging in these resources…

- How To Choose The Right Packaging To Protect Your Products? [Podcast]

- Packaging Inspection Guideline: What Is Usually Checked?

- Packaging: How to Protect your Shipment Effectively?

- How to test the protection of your products during transport

- Plus – Remember to read our new Importer’s guide to 9 types of packaging over on Sofeast:

Just hit the image below to read it (no downloads required).

It includes:

- 9 types of packaging (which are suitable for a handheld size product)

- Types of dunnage (interior packing)

- Electronics packaging

- Reusable packaging

- Next steps after products are packaged