One of the most frustrating aspects of working with Chinese suppliers is that, for the most part, they don’t want to (or cannot) conduct a root cause analysis.

Let’s say you found a serious issue in one of your productions and you don’t want it to come back in the future. You ask for an investigation into that problem. And they come back with very superficial responses that are clearly still far from exposing root causes.

Here are very common excuses:

- “It is due to an issue on the components; the supplier made a mistake and we are asking them to pay more attention to it in the future.”

- “The operator made a mistake, but as you know it is a manual process so it happens”

- “We will ask the inspection team to check this carefully in the future”

- “This is a very serious problem, and it is due to the line supervisor’s lack of compliance with our boss’ orders. We are going to replace him.”

I wrote before about this topic:

- Many companies’ managers are stuck “fighting the fires of the day” rather than tackling one problem at a time and preventing it from recurring.

- Many manufacturers ask their quality manager to handle their customer’s complaints so as to deflects blame, not in a way that drives improvement.

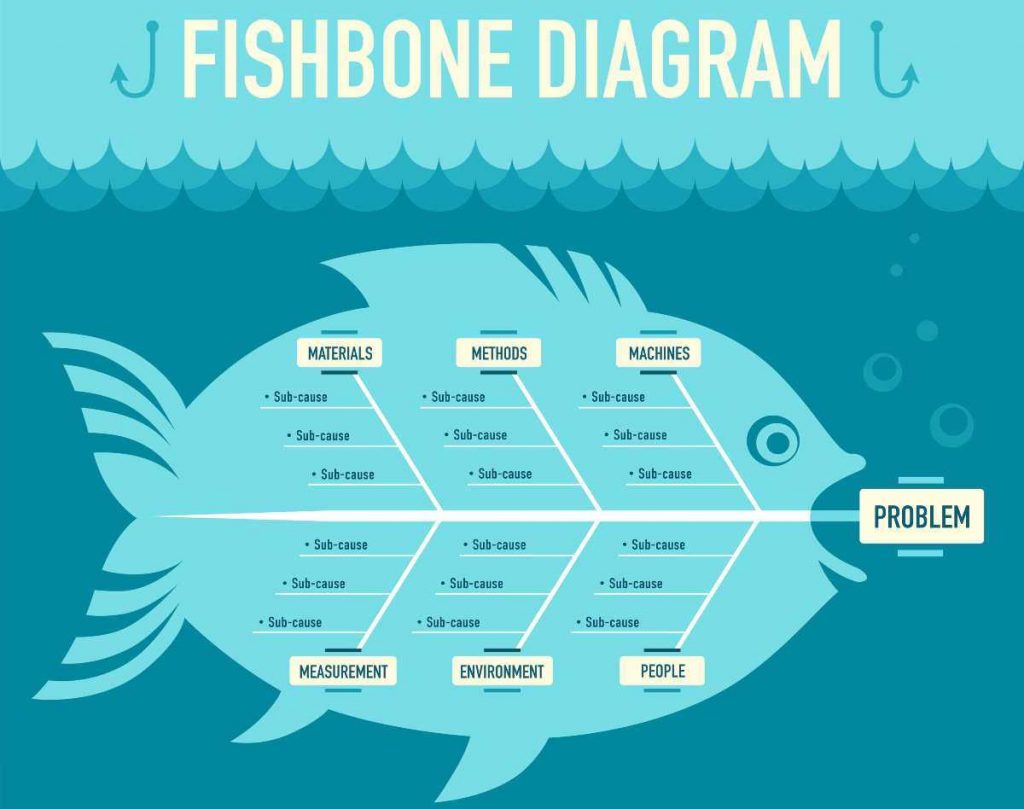

- To a certain extent, a simple flow chart can help guide an investigation.

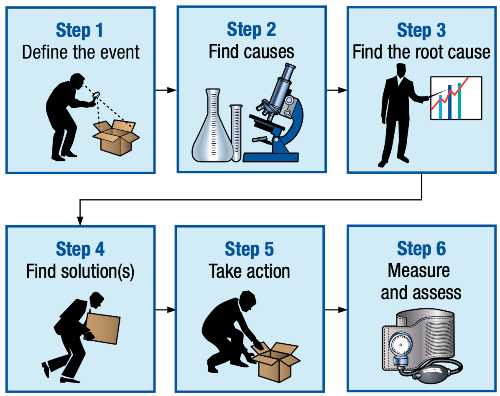

- I gave an overview of the steps to follow in a root cause analysis here.

The Root Cause Analysis Method For Finding & Stopping Problems Reoccurring

And I just found a nice resource: the ASQ Pocket Guide to Root Cause Analysis.

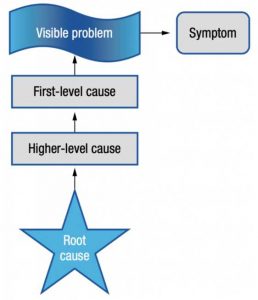

It explains what the difference is between a symptom, a problem, and the different levels of causes:

It then goes through the 6 steps of addressing a problem so that it doesn’t recur:

The authors do a nice job of guiding the reader through a number of useful tools, in each step. They take a wide variety of examples, so it is not focused on manufacturing.

You will notice it is quite close to the approach of filling an 8D report. And that’s normal. Apart from forming a team and doing a short-term containment, the whole approach is quite similar.

**********

Have you been able to guide some of your key suppliers in doing proper investigations into their problems, in a way that drives improvement? What worked, and what didn’t work?

Are you wondering how to find a manufacturer in China who is well-suited to your needs and can also deliver on their promises?

Sofeast has developed 10 verification steps to help you find the right manufacturer. They’re shared in this FREE eBook: “How To Find A Manufacturer In China: 10 Verification Steps.”

It covers:

- Background checks

- Manufacturing capabilities

- Quality system auditing

- Engineering resources

- Pricing, negotiation, & contracts

- …and much, much more

Just hit the button below to get your copy: