In this episode… Dan Harris from China Law Blog recently wrote: "Mexico is the New China" and Manufacturers are Moving There. Renaud Anjoran and Adrian from the team explore the topic of nearshoring to locations like Mexico, why it may … [Read more...]

Supply Chain Risk Management: No, Toyota Doesn’t Always Do Just-In-Time

I ran into a very interesting article from Bloomberg entitled How Toyota Steered Clear of the Chip Shortage Mess. Nearly all automakers announced that they would have to cut their production numbers due to a serious shortage of … [Read more...]

Have You Revised your Supply Chain Risk Analysis?

Last year, I wrote about the Business Continuity Plan (BCP). More and more companies request their suppliers to prepare a BCP, as a structured approach to performing a supply chain risk analysis to get prepared for the risks they are … [Read more...]

Richard Barnett | Electronics Supply Chain Risk Management in 2021 [Podcast]

Let's hear from an electronics supply chain expert about how to improve supply chain resilience and reduce risks... Richard Barnett of Supplyframe, an expert in electronics supply chains with decades of experience in Asia, joins … [Read more...]

Why Do Importers Need Product Reliability Testing? [Podcast]

Product reliability testing is a must for importers who want to avoid risk... 2020 added considerable strain and difficulty to many importers' lives, so today, more than ever, it's so important to implement measures to protect your … [Read more...]

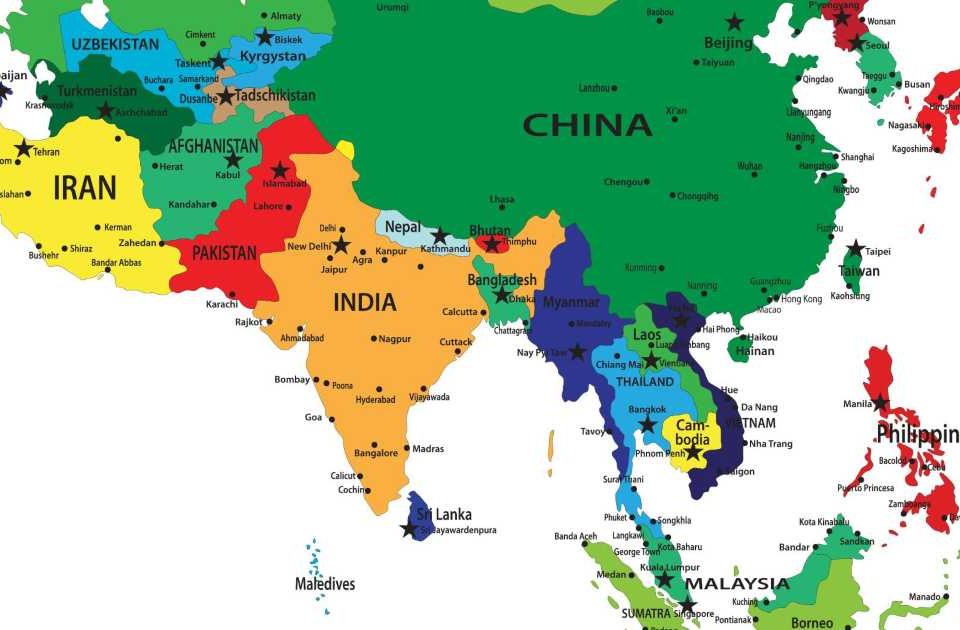

Manufacture in China, Vietnam, India, or Elsewhere in 2021? [Podcast]

Manufacturers continue to plan the move of some or all of their supply chains out of China? But where next? Perhaps the word 'exodus' is a little over-dramatic, but there has certainly been a marked rise in companies trying to diversify … [Read more...]

How To Perform In-Depth Due Diligence On Your Supplier [Podcast]

Do your new or current suppliers pose a risk to your business? Sometimes the only way to find out if a supplier poses a risk is to perform some deep due diligence on them in order to assess their business health and if they're able to be a … [Read more...]

7 Manufacturing Challenges Due To Lack Of Transparency In China & How To Mitigate Them [Podcast]

The situation in Hong Kong, the US/China trade war, mistrust of China and attempts at decoupling, and other news stories are rightfully a cause of concern for importers with Chinese suppliers. But the manufacturing challenges you should be … [Read more...]

Supply Chain Risk Management, Part 5: Moving Manufacturing to Vietnam, Thailand, Malaysia, or India (Pros & Cons)

One of the main conclusions of many companies is as follows: 'diversifying our supply chain outside of China is a must in order to reduce risk'. There are two main reasons for this. First, the USA has been leading the charge against … [Read more...]

Supply Chain Risk Management, Part 4: How Much Inventory Do You Need?

If you make sure to sit on 6 months of inventory for every one of your major products, you will run much lower risks of being unable to supply your customers with what they need. You might even be able to cut a current manufacturer off and … [Read more...]

![How Does Mexico Compare To China As A Manufacturing Base? [Podcast]](https://qualityinspection.org/wp-content/uploads/2021/08/HowDoesMexicoCompareToChinaAsAManufacturingBasePodcast-960x627.jpeg)

![Why Do Importers Need Product Reliability Testing? [Podcast]](https://qualityinspection.org/wp-content/uploads/2021/01/WhyDoImportersNeedProductReliabilityTestingPodcast-960x630.jpg)

![Manufacture in China, Vietnam, India, or Elsewhere in 2021? [Podcast]](https://qualityinspection.org/wp-content/uploads/2020/12/ManufactureinChinaVietnamIndiaorElsewherein2021Podcast-960x600.jpg)