The horrific invasion of Ukraine and the resulting sanctions on Russia are starting to have effects that importers & exporters are feeling. Combined with the consequences of covid outbreaks and the already very high shipping prices, … [Read more...]

Supply Chain Risk Management: No, Toyota Doesn’t Always Do Just-In-Time

I ran into a very interesting article from Bloomberg entitled How Toyota Steered Clear of the Chip Shortage Mess. Nearly all automakers announced that they would have to cut their production numbers due to a serious shortage of … [Read more...]

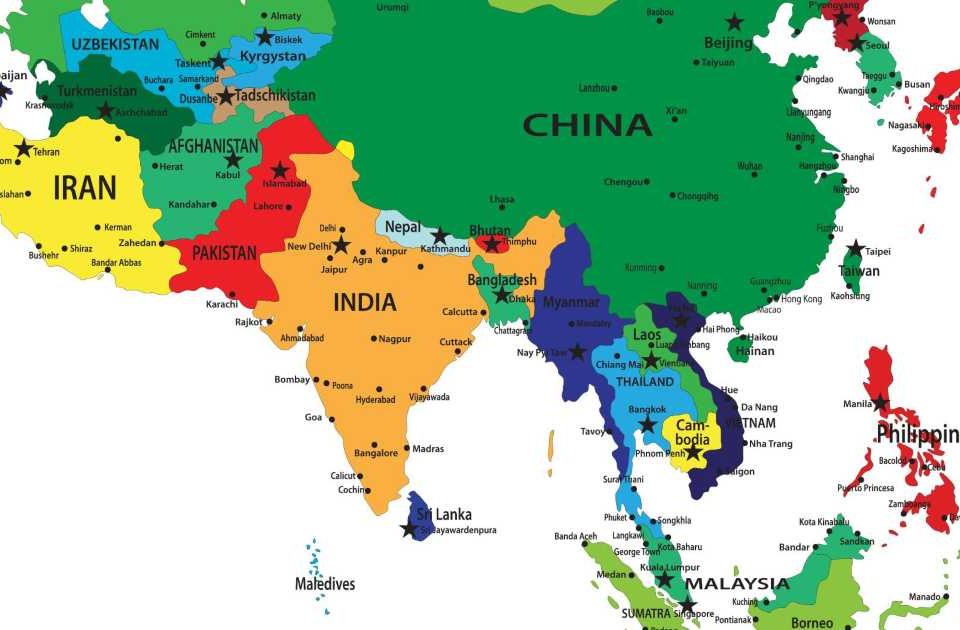

Manufacture in China, Vietnam, India, or Elsewhere in 2021? [Podcast]

Manufacturers continue to plan the move of some or all of their supply chains out of China? But where next? Perhaps the word 'exodus' is a little over-dramatic, but there has certainly been a marked rise in companies trying to diversify … [Read more...]

How To Perform In-Depth Due Diligence On Your Supplier [Podcast]

Do your new or current suppliers pose a risk to your business? Sometimes the only way to find out if a supplier poses a risk is to perform some deep due diligence on them in order to assess their business health and if they're able to be a … [Read more...]

Supply Chain Risk Management, Part 5: Moving Manufacturing to Vietnam, Thailand, Malaysia, or India (Pros & Cons)

One of the main conclusions of many companies is as follows: 'diversifying our supply chain outside of China is a must in order to reduce risk'. There are two main reasons for this. First, the USA has been leading the charge against … [Read more...]

The End Of Just In Time Manufacturing? [Podcast]

A number of blog posts, such as this one, have been popping up lately casting doubts on whether just in time manufacturing can survive post-coronavirus. They share some pretty strong words: Recent trade tensions between the US and … [Read more...]

Some Chinese Factories Are Going Bankrupt: How To Know Which Ones

Some Chinese factories have suffered serious blows recently. Large American companies are moving manufacturing outside of China, often abruptly. Many manufacturers were hit in 2020 by very soft demand and cancelled orders. Their … [Read more...]

Supply Chain Risk Management, Part 4: How Much Inventory Do You Need?

If you make sure to sit on 6 months of inventory for every one of your major products, you will run much lower risks of being unable to supply your customers with what they need. You might even be able to cut a current manufacturer off and … [Read more...]

Will China Lock Entire Provinces Down A Second Time in 2020?

In early February, I was wondering what effects the lockdown of China would have on importers. And, a few weeks later, importers suffered another (often more violent) blow: stores closed for months, a lot of unsold inventory, and weak … [Read more...]

China’s Corporate Social Credit System: Watch Out For Supplier Risk!

Recently, I watched a webinar entitled "China's corporate social credit system: evaluating the impact on your supply chain". It was organized by the European Chamber of Commerce in China, and the Head of Risk Consulting at KPMG provided … [Read more...]

![Manufacture in China, Vietnam, India, or Elsewhere in 2021? [Podcast]](https://qualityinspection.org/wp-content/uploads/2020/12/ManufactureinChinaVietnamIndiaorElsewherein2021Podcast-960x600.jpg)

![The End Of Just In Time Manufacturing? [Podcast]](https://qualityinspection.org/wp-content/uploads/2020/08/TheEndOfJustInTimeManufacturingPodcast-960x630.jpg)