A client was interested in product inspections, and they asked:

Do you also offer a post-inspection service, for cases where the results are not ideal?

That got me thinking.

The answer is simple, yes, we can keep following up, but managing the way rework is done and planning a re-inspection is never a pleasing experience for the buyer.

It looks straightforward (see below), but in reality, it is often a tense negotiation between the buyer and the seller:

How to avoid post-inspection negotiations? Put your focus on all the pre-production steps!

Get all your ducks in a row before starting to send any money to the supplier.

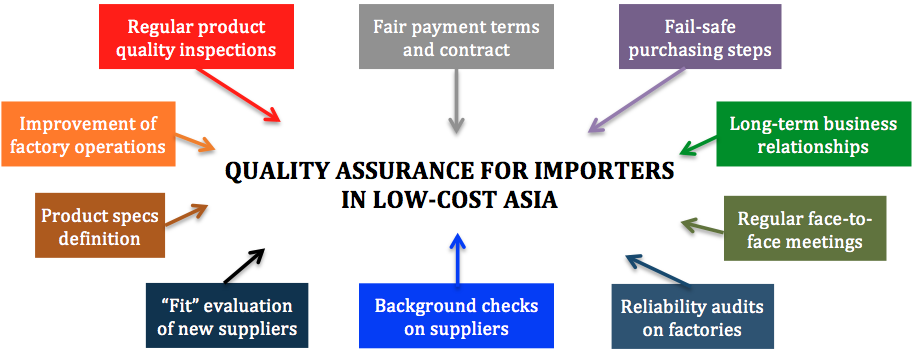

If you purchase standard off-the-shelf products, you should refer to an article I wrote a few years ago — A Good Quality Assurance Strategy in China.

Here are the 10 components I suggested at the time. Years later, I have nothing to add to the list:

Here is how these elements will help you, should quality issues be found by your inspector:

- When sourcing a supplier, make sure there is a good “fit” between your company and theirs. Doe due diligence on them. Meet them regularly if you can. Don’t do business with a short-term perspective. All this maximizes the chance that you work with a supplier that will try to do a good job.

- Define your product specifications and your quality standard. I wrote advice on that. This way, the manufacturer cannot say “we thought it was OK”. (And, hopefully, the issues don’t come up at all.

- Set the right contract with the supplier before you wire any money. It will give you much more leverage to force them to do rework and to pay for the re-inspection. China’s court system is not great, but a contract does help.

What if you work with a Chinese manufacturer to develop new products?

You still need to do everything I described above.

And, in addition, if you are investing a lot of money in developing an electrical and/or mechanical product, you need to follow some very deliberate steps. Otherwise, many of the products may not even work, and you won’t know why.

I explained that structured process in this video from my company, Sofeast:

This NPI process is also part of the quality assurance strategy. It helps tremendously with product reliability and safety, too.

******

What about you? Have you run into difficulties when dealing with a supplier that made substandard products? How did you persuade them to take the right steps to ensure good products were finally shipped out? Let me know by commenting, please.

Get expert help to improve YOUR product quality from suppliers in China or Vietnam. Read: Quality Assurance In China Or Vietnam For Beginners

Download your free copy of Sofeast’s eBook and learn the common traps new importers from China or Vietnam fall into, and how to avoid or overcome them in order to get the best possible production results. It also outlines a proven quality assurance strategy that you can follow in order to have better control over your product quality, covering:

- Finding Suitable Suppliers

- Defining your Requirements before Production Starts

- Don’t Skip the New Product Introduction Process

- Regular Quality Inspections (Trust but Verify)

- Tying Payments to Quality Approvals

Sounds good? Hit the button below to get your copy now: