Do your new or current suppliers pose a risk to your business? Sometimes the only way to find out if a supplier poses a risk is to perform some deep due diligence on them in order to assess their business health and if they're able to be a … [Read more...]

Archives for October 2020

Investigating the Causes of Product Failure and Improving Design

You conduct reliability tests on your new products. You and your suppliers do product inspections and laboratory tests on mass production orders. Your customers probably give you feedback on the issues they find on what you ship to them. … [Read more...]

The Basics of Quality Management for Buyers [Podcast]

What's the best way to get started with quality management? It makes a lot of sense to work to improve your product quality coming from Chinese suppliers and you don't need to be a large corporation to do this, but this kind of quality … [Read more...]

Should You Avoid the Words “Defects” and “Defectives”?

Someone on Linkedin wrote about the distinction between these 2 terms: Defect Defective I actually see a lot of confusion around them. What does the standard say? ISO 2859-1 includes these definitions: Defect: … [Read more...]

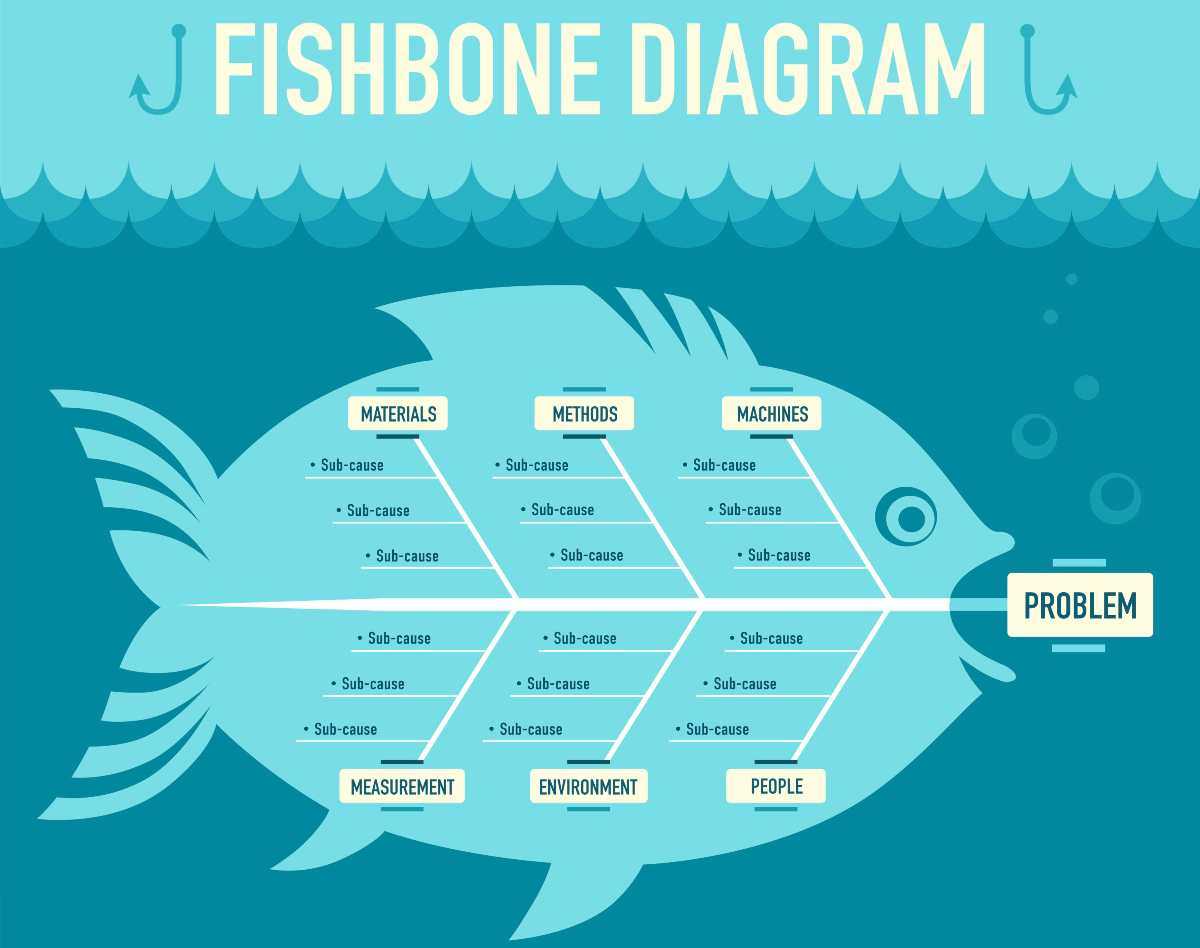

An Introduction to Root Cause Analysis (Not Just for Manufacturing)

One of the most frustrating aspects of working with Chinese suppliers is that, for the most part, they don't want to (or cannot) conduct a root cause analysis. Let's say you found a serious issue in one of your productions and you don't … [Read more...]

Factory Testing Facilities | Vetting Chinese Suppliers (Part 8) [Podcast]

Why do we look at the factory testing facilities when vetting a Chinese supplier? A great question here is: "How can my supplier know that the product they're manufacturing is good if they're unable to test that they reach my … [Read more...]

Using Reliability Engineering for Designing a More Durable Product

Many leading brands have had to address concerns over the impact of their products on the environment. And one of the best responses is "make products that last longer". Here are the responses of two iconic brands: Apple: make … [Read more...]

Dangers of Amortizing Development Costs in the Production Price

When I offered a model for guiding buyers to choose an ODM vs. OEM vs. CM supplier, I mentioned that OEM suppliers often "subsidize" the cost of developing the new product. Then, the buyer ends up paying the cost of development, but it is … [Read more...]

What Is Compliance Testing? [Podcast]

Why is compliance testing so important for buyers who import products from China? Compliance testing helps assure your product's compliance with your market's product and safety standards. By conducting such testing, you'll be … [Read more...]

Defining and Enforcing Manufacturing Processes for Better Control

As David Collins from CMC often says, there are 5 key success factors that determine a factory’s performance: Production Planning, Incoming Material, Workforce Training, Process Control and Equipment Maintenance. In this article, I'd … [Read more...]

![Factory Testing Facilities | Vetting Chinese Suppliers (Part 8) [Podcast]](https://qualityinspection.org/wp-content/uploads/2020/10/FactoryTestingFacilitiesVettingChineseSuppliersPart8Podcast.jpg)